CHALLENGE TO

CARBON NEUTRALITY

Accelerate inverter (Inv) adoption globally and lead the industry with eco-friendly products (energy-efficient equipment).

➢ Room air conditioner Inv adoption rate: 2019: 75% → 2021: 79% → 2025 target: 93%

➢ Develop and expand sales of detailed system energy-saving technologies.2. Expansion of Heating and Hot Water (H/P) Business

Europe: Aim to be the market leader in major countries and launch new products using R290.

North America: Accelerate sales of Inv and H/P unitary product “FIT.”

China: Expand sales of H/P floor heating systems.

Japan: Increase sales of EcoCute and high-heating H/P for cold regions.3. Refrigerant Initiatives Supporting the Air Conditioning Business

Choose the most suitable refrigerants for each region, promote natural refrigerants, and scale up mass production.

➢Promote R32 adoption globally—expand R32 use for VRV systems in Japan and Europe.

➢Develop equipment using natural refrigerants and conduct risk assessments.

➢Develop next-generation refrigerants (for automotive and air conditioning applications).

4. GHG Emission Reductions in Manufacturing, Development, and Office Operations

Strive for net-zero GHG emissions across all factories (excluding chemicals) by 2030.

➢ Achieve net-zero emissions at Sakai and Rinkai factories ahead of schedule by FY23.

➢ Achieve net-zero emissions at major domestic offices by FY25 and globally by 2030.

5. Challenges in New Businesses for a Carbon-Neutral Society

Strengthen initiatives in negative emissions and power-related activities.

➢ Expand micro-hydropower sales and explore opportunities in power-related businesses.

➢ Pursue technologies for CO2 capture and utilization (DAC1, CCU2).

*1. DAC: Direct Air Capture of CO2 from the atmosphere.

*2. CCU: Carbon Capture and Utilization.6. Circular Economy Initiatives

Accelerate the global construction of a refrigerant eco-cycle (recovery and regeneration).

Strengthen circular economy efforts for other materials by promoting recycled materials and improving durability.

➢ Establish refrigerant recovery and regeneration networks in regulated regions (Europe, Japan, North America).

➢ Material initiatives beyond refrigerants (plastics, metals, etc.):

・Utilize recycled plastics, aluminum horizontal recycling (*3), and reduce rare earth usage.

*3. Horizontal recycling: Recycling where used products are returned to raw materials and then reborn as the same type of product.

- Energy Saving Technology

- Refrigerant Development

- Heat Pump Heater & Expansion Of Hot Water Supply

- Energy Creation Technology

ENERGY SAVING TECHNOLOGY

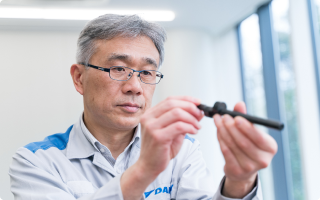

Creating a compressor requires a wide range of knowledge including knowledge of structure, fluids, acoustics, heat, lubrication, materials, and basic experimental and analytical techniques.

TIC mechanical designers perform research and development with an inquisitive mind for the important components that support Daikin products since the need for precision in air conditioners rivals that needed in automobile engines.

Increase the leading position that Daikin air conditioners have in the world.

(1) Typical compressor motors rotate only by the force of permanent magnets, but we have achieved an industry first with the practical application of a motor with an embedded magnet structure that also uses the magnetic force attracting iron. This contributes to energy savings in residential and commercial air conditioners.

We are also working to reduce the amount of heavy rare earths used in permanent magnets.

(2) For fan motors, we are contributing to the reduction of fan energy with development of the industry's first outer rotor type permanent magnet motor that can be integrated with a fan.

・Halve rare earth usage in the magnets used for rotors in compressor motors.

・Replace copper wire with aluminum wire for use in the fan motor stator.

Daikin Industries globally develops distinctive inverter products, including low-cost inverter air conditioners that use electrolytic capacitors, and inverters are developed as a core technology at TIC. Additionally, inverters are a technological field supported by industry-academia collaborative innovation and industry-industry collaborative innovation, and we will continue to promote technological development specialized for applications while valuing collaborative innovation.

Create new value while improving energy savings and cost.

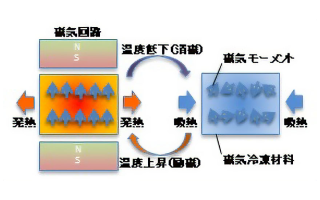

In aiming for practical application in the future, investigation is being done on the feasibility of a magnetic refrigeration heat pump that is suitable for the high-performance magnetocaloric materials currently being

Obtain development guidelines for high-efficiency, non-fluorocarbon heat pump air conditioners.

REFRIGERANT DEVELOPMENT

Our efforts also include proposing and implementing refrigerants with low Global Warming Potential (GWP) in air conditioning products, developing technologies to quickly detect refrigerant leaks from air conditioning systems, and collaborating with stakeholders on the recovery and regeneration of used refrigerants, all aimed at achieving net-zero GHG emissions.By leveraging IoT, AI, and open innovation, we strive to address global environmental challenges, meet the world's air-related needs, and provide safe and healthy air environments.

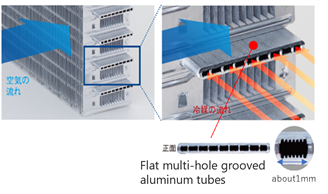

Daikin utilized its own technology to incorporate the heat exchanger typically used for an automobile air conditioner (for cooling only) and adapt it for its unique “micro channel heat exchanger,” which was installed in an air conditioner outdoor unit for both cooling and heating to achieve a world’s first in 2012.

Compared to conventional cross fin heat exchangers, it weighs less due to its all-aluminum construction, provides higher performance by its smaller tube size, and reduces the amount of refrigerant, a cause of global warming, in addition to reduced size.

The manufacturing process and equipment have been renovated, and Daikin has rewritten 50 years of cross-fin history to take the global lead in heat exchanger technology through its worldwide adoption of its microchannel heat exchanger to its air conditioners.

Contribute to reduction of environmental impact by saving refrigerant and improving energy savings with development to indoor units

HEAT PUMP HEATER &

EXPANSION OF HOT WATER SUPPLY

to accelerate conversion from combustion type

to heat pump type heating systems

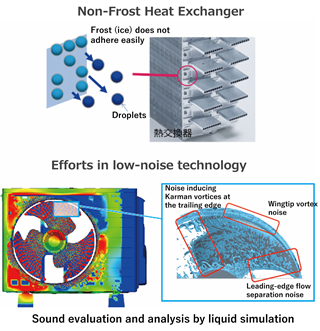

As outdoor temperatures drop in winter, frost can form and accumulate on the heat exchanger surface of the outdoor unit during the heating operation of a heat pump type air conditioner. That frost can prevent air from blowing to the air conditioner and degrade performance. In that case, the heating operation stops and warm refrigerant flows to the outdoor heat exchanger to melt the frost (defrost operation).

This is the biggest challenge in replacing combustion heating with heat pump heating, and to solve this problem, we are developing technology to desorb condensation generated in the outdoor heat exchanger during heating in the form of droplets from the heat exchanger before it turns to frost.

Market needs for low noise are extremely high, particularly in Europe. This is why we are developing technologies to reduce blower noise from fans and other components by identifying the source of the noise through fluid simulation and analyzing airflow around the fan to optimize fan shape to suppress vortex generation, a cause of noise.

Contribute to the global environment through the widespread adoption of heat pump heaters.

ENERGY CREATION TECHNOLOGY

Number of installations: 46 locations (as of January 2024).■A startup from TIC. From "energy conservation" to "energy creation

DK-Power, Ltd. | About Micro Hydro Power Generation