Packaged Air Conditionersfor Facilities & Factories

Success at research facilities and factories often hinges on strict control of air temperature and quality. To these environments, Daikin offers an abundant range of packaged air conditioners for precise control of air and temperature to help preserve accurate results and product quality.

Daikin Advantage

Energy and Cost Savings

Using advanced inverter and heat pump technologies increases efficiency and reduces energy consumption and costs.

Wide Range of Solutions

Daikin provides a lineup to a wide range of applications that require high precision in temperature control and air quality.

Control by Zone / Area

Daikin packaged air conditioners combine with ducts to distribute air only to zones and areas where needed.

Application

Technology

Inverter Technology

Air conditioner compressors are driven by motor, and motor rotation speed depends on power supply frequency. An inverter modulates power supply frequency to control motor rotation speed. Inverters stabilize temperature by adjusting compressor operation according to load to eliminate waste and save energy.

Even adopting an inverter to the fan motors of the indoor and outdoor units provides more precise control and contributes to energy savings.

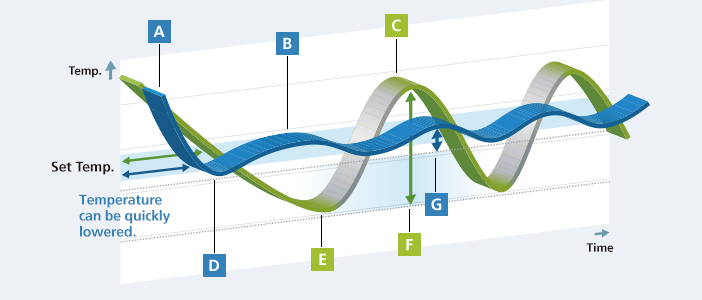

Temperature Control by Inverter/Non-Inverter Compressors (Cooling)

When temperature is higher than set temperature, the motor rotates faster to lower room temperature.

Motor rotation speed is adjusted to maintain a constant temperature.

Motor rotates when temperature is higher than set temperature.

When temperature approaches set temperature, the motor rotation speed is reduced.

Motor stops when temperature is lower than set temperature.

Variation width for temperature becomes large when temperature is adjusted by repeatedly starting and stopping the motor. Furthermore, the motor always rotates at constant speed, and energy consumption increases from the energy loss of starting and stopping.

Lowering motor rotation speed according to load reduces both variation width for temperature and energy consumption.

WE RECOMMEND

Additional Information

First Packaged Air Conditioner in Japan

In 1951, Daikin launched Japan's first packaged air conditioner to provide turnkey operation and begin its lead as pioneer in the commercial use air conditioning market.

Daikin and Refrigerants

Daikin is a comprehensive manufacturer that also produces the refrigerant used in its air conditioning equipment.

After Sales Service

A global support system delivers timely solutions to all needs.

Learn MoreRelated Products

Preventive Maintenance Service

To ensure greater energy savings, long product life, and comfort, Daikin offers these services.

AVAILABILITY

The products or features on this page may not be available in your region.

Please visit your local website for details on the products and features available in your region.

WE RECOMMEND

Find out more in your region.