Kagawa: While majoring in chemistry in the department of science at my university, I conducted research that utilized the properties of elements like sulfur and selenium. Daikin has a chemicals business that specializes in fluorine, so that connection between my university research and a company business field made me want to join Daikin. Upon entering the company, I became involved in launching new businesses and spent around 10 years in researching and scaling up electrolyte solvents, giving me experience in various aspects ranging from the lab to the field and then to quality assurance. However, in 2015, when TIC was established, I was transferred, and since then, I have been doing research based on collaborative creation themes involving functional coatings and air conditioning.

NEWS

Commitment as an HVAC Equipment and Refrigerant Manufacturer to Recover and Reclaim All Refrigerants

Kagawa: While majoring in chemistry in the department of science at my university, I conducted research that utilized the properties of elements like sulfur and selenium. Daikin has a chemicals business that specializes in fluorine, so that connection between my university research and a company business field made me want to join Daikin. Upon entering the company, I became involved in launching new businesses and spent around 10 years in researching and scaling up electrolyte solvents, giving me experience in various aspects ranging from the lab to the field and then to quality assurance. However, in 2015, when TIC was established, I was transferred, and since then, I have been doing research based on collaborative creation themes involving functional coatings and air conditioning.

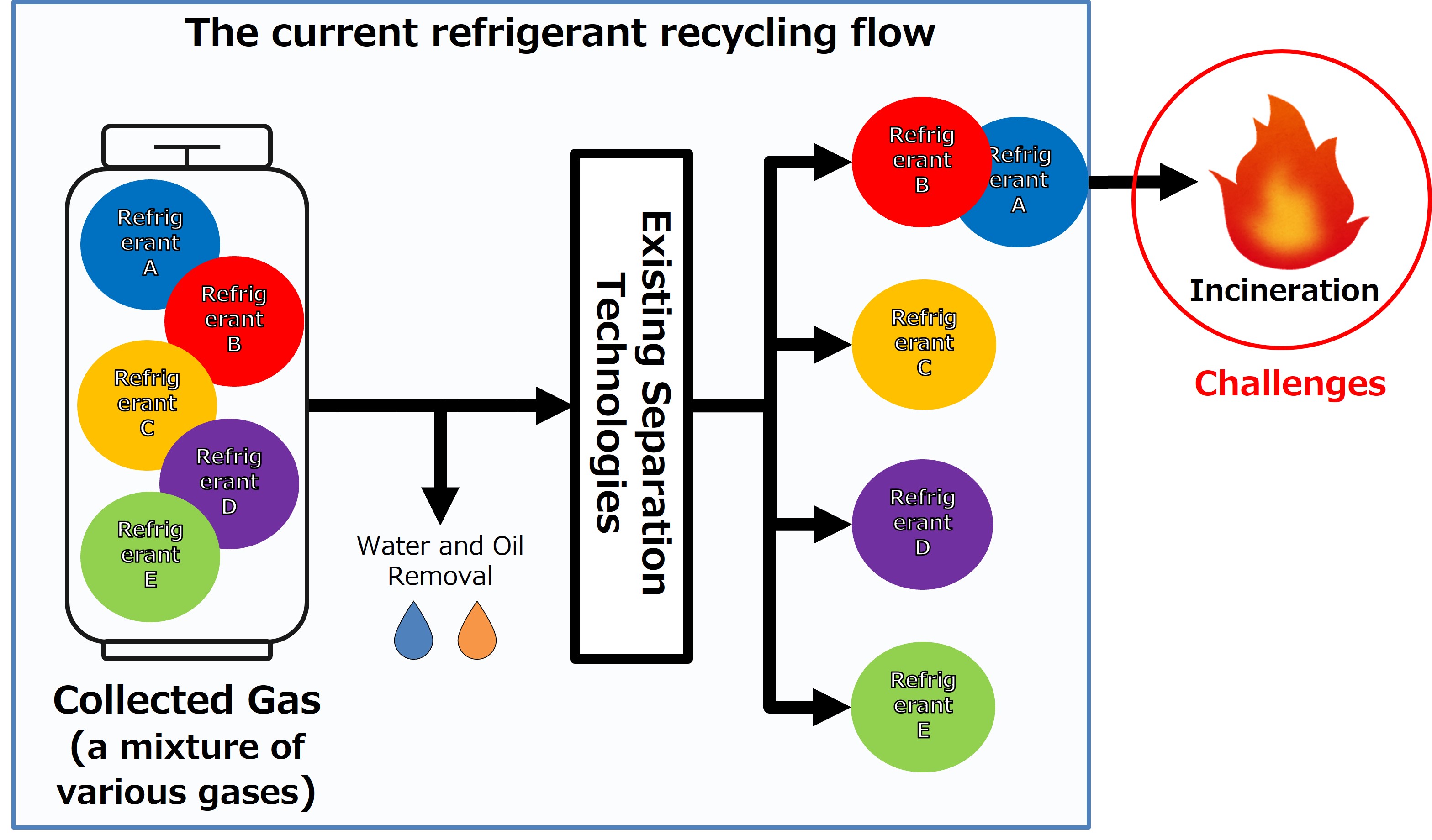

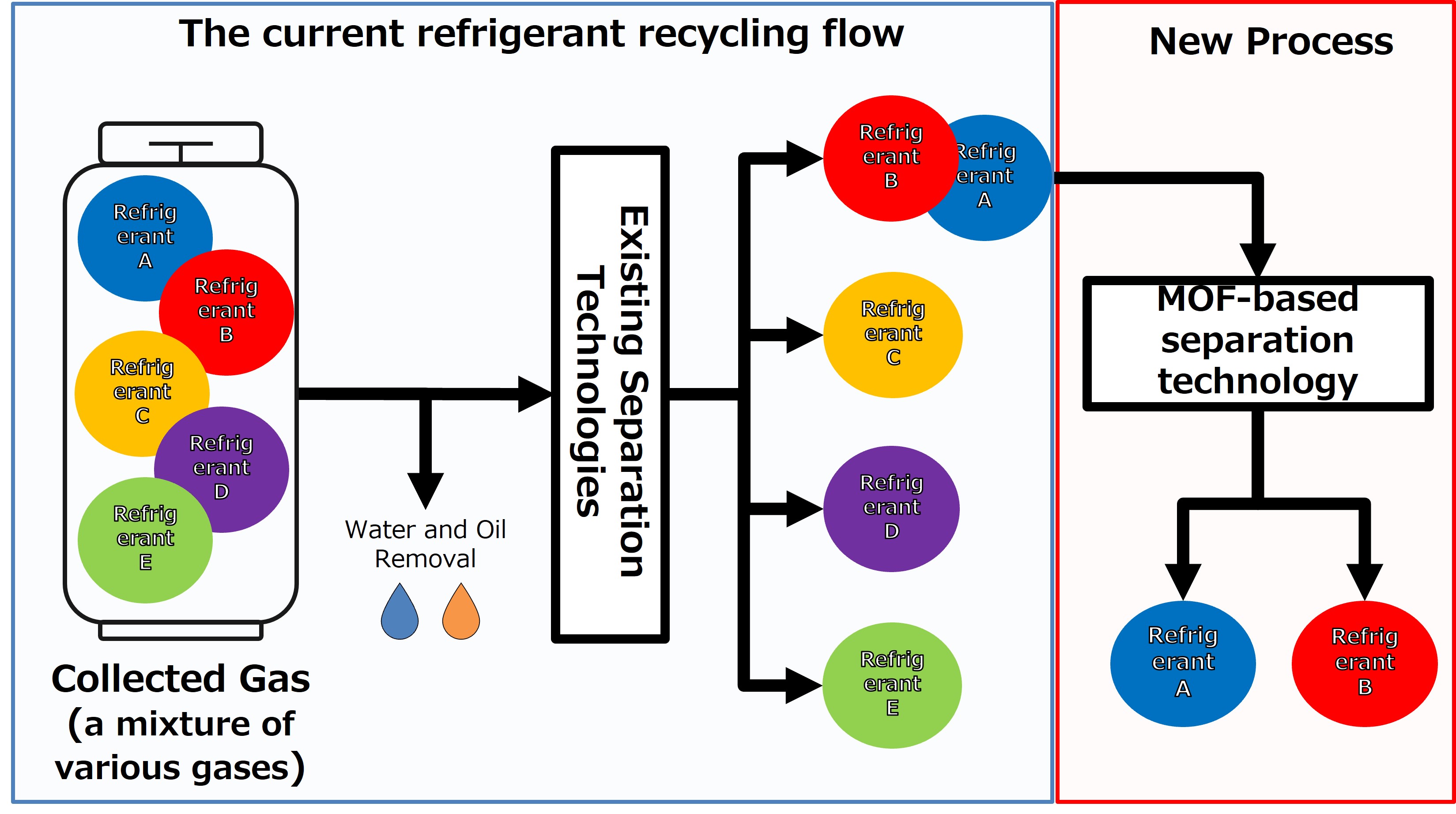

Hagita: One of the most challenging issues for refrigerant recovery and reclamation has been the lack of any existing technologies that could separate certain refrigerants, which has given us no other choice but to incinerate them. Often, it’s because the recovered refrigerant gas is a refrigerant blend having a mixture of refrigerant gases. Until now, we would remove the water and oil before applying separation techniques, but because distillation is used for separation, refrigerants with similar boiling points could not be separated and had to be incinerated. By adopting a new separation technology using metal-organic frameworks (MOFs), we succeeded in separating refrigerants that had previously been unfeasible to do so. Promoting refrigerant recovery and reclamation contributes to achieving a circular economy, both economically and environmentally.

Tunable Porous Materials Solve Refrigerant Separation and Environmental Issues

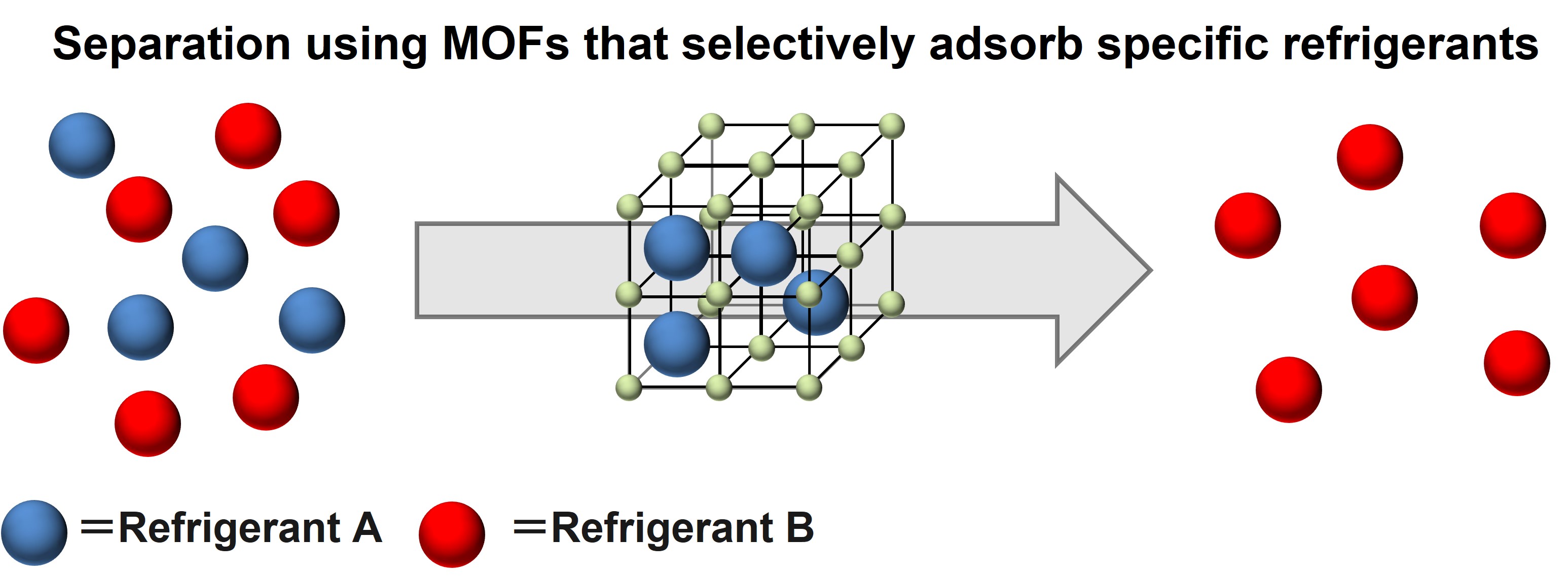

Hagita: MOF stands for metal-organic framework, and that describes a structure composed of metals and organic ligands. MOFs have tiny pores, and by adjusting the size of these pores and introducing interactions tailored to specific adsorbents, they can selectively adsorb specific refrigerants and physically separate them. MOFs were developed by Atomis, a venture originating from Kyoto University, and we are collaborating with Atomis to develop MOFs specialized for refrigerant reclamation. One distinctive advantage of this technology is having the ability to finely adjust and create MOFs with various pore sizes to match different types of refrigerants.

TIC has had a history of addressing environmental concerns, and we have been researching ways to improve existing technologies. In the purification of refrigerants, fractional distillation techniques utilizing differences in boiling points for refrigerant separation have been employed. However, one of the challenges of this method is its inefficiency in separating refrigerants with small differences in boiling points. Additionally, the energy consumed to heat refrigerants to their boiling points during distillation is relatively high.

Physical separation via adsorption requires less energy compared to distillation, offering an advantage. While searching for a suitable adsorbent, we learned about MOFs and began researching their applicability to purification techniques, believing this technology could be used in the field of refrigerant purification.

Kagawa: Yes, that's correct. Reclaiming refrigerants without incinerating them can reduce CO₂ emissions and increase production. According to the Kigali Amendment to the Montreal Protocol, an international treaty, hydrofluorocarbons (HFCs) used in refrigerants need to be reduced in advanced countries by 85% from the 2011-2013 baseline in terms of CO₂ equivalent values by 2036. Instead of creating new refrigerants, the trend is moving toward recovering and reclaiming refrigerants already on the market. Daikin, being a company that manufactures and sells both refrigerants and air conditioning equipment, aims to lead the way in this cycle ahead of others and is actively promoting the reclamation business.

Creating experimental equipment and verifying specifications and their effectiveness by trial and error

Kagawa: Collaborating with other companies is common and a core mission of TIC. We have many examples of collaborative research for various other research themes. In this case, creating MOFs from scratch and creating a business would have been extremely challenging, given that it would require both expertise and development time that we didn’t have. We shared the details of our processes with Atomis to a significant extent, and Atomis, being experts in MOF manufacturing and simulation, conducted multifaceted evaluations of MOFs. Our side then performed the verification experiments. This cyclical approach allowed us to develop with a sense of unity and speed, which we consider to be the benefits of this collaboration.

Kagawa: The research began in 2020, and now we are in the third year. Since MOFs themselves are a new material, it was a challenge to verify the specifications and effectiveness when using them as adsorbents in the process. We struggled with the verification process, questioning whether they had the required performance for refrigerant separation and whether they could withstand real-world application. Additionally, the methods for verification were not well-established, so we had to start from the very beginning.

Both MOFs and the refrigerant separation process using them are novel technologies, and the assembly of the process could not be accomplished by TIC alone. For this reason, we collaborated with departments in other divisions, such as the Chemicals Division.

Applying MOFs to refrigerant separation also presented experimental nightmares. We had to create our experimental equipment from zero. Even though we could visualize the process in our minds, figuring out the specific conditions and equipment was a significant hurdle. Initially, I started the research by myself, so I faced various difficulties along the way.Hagita: Not only did we face technical challenges, but we also struggled with communication when introducing this technology to our group's locations. We were unable to effectively communicate through emails and online meetings alone. It was by visiting and meeting the responsible parties in person that we were able to understand each other better, which made communication easier and sped up the development process. Currently, development is progressing from the 8th to the 9th stage, and it is expected to be completed soon. It is anticipated that the technology will be progressively applied to product recycling within the fiscal year 2023.

An environment where someone always lends a helping hand once the need is understood

Kagawa: One of the great aspects of Daikin is that when you're in trouble and seek help, someone will always lend their expertise. This culture has been consistent since I joined. Even though I initially struggled on my own with this project, once I managed to make my intentions understood within the company, more and more people extended a helping hand to me. I believe this is the case for people in all departments.

Hagita: I joined as a mid-career hire and was impressed by seeing so many specialists in a variety of fields, which made it an interesting company to me. It's not just about air conditioning: there are people from the field of chemistry who conduct a broad range of research. As Kagawa mentioned, it’s a flat organization with very few barriers between departments, creating an atmosphere where it's easy to consult with people from other departments when you are faced with a problem. In that sense, it's an environment that makes development easier. I'm currently responsible for another project, and I was able to solve issues by consulting with experts in the adsorption/separation process. In that project, we also perform simulations on PCs, and I learned to use specialized software for that purpose.

Kagawa: Daikin is a company that truly allows you to take on challenges when you want to create something new, and that’s an approach that researchers and developers can truly appreciate. This adsorption technology that we've been working on fascinated me during its research, but I never imagined it would evolve into something this significant. When your actions and enthusiasm align, you can see your research materialize. I strongly feel that this is the appeal of Daikin.

Hagita: I feel the same way but from the perspective of someone coming from another company. For me, it's an interesting workplace to see people from various fields. Also, at TIC, there are abundant high-value analytical instruments, creating a conducive environment for research. If you have the motivation and a well-defined development narrative, it's an environment that allows you to take on challenges.

Technology and Innovation Center Senior Engineer

Joined in April 2004. Originally from Nagano Prefecture, she is responsible for refrigerant separation technology.

“I aim to contribute to future environmental businesses through unique technology development at TIC.”

Technology and Innovation Center

Joined in November 2018. Originally from Kyoto Prefecture, he is responsible for refrigerant separation technology.

“I aspire to take on the challenge of developing various reclaiming technologies that consider not only refrigerant reclamation but also the global material cycle.”