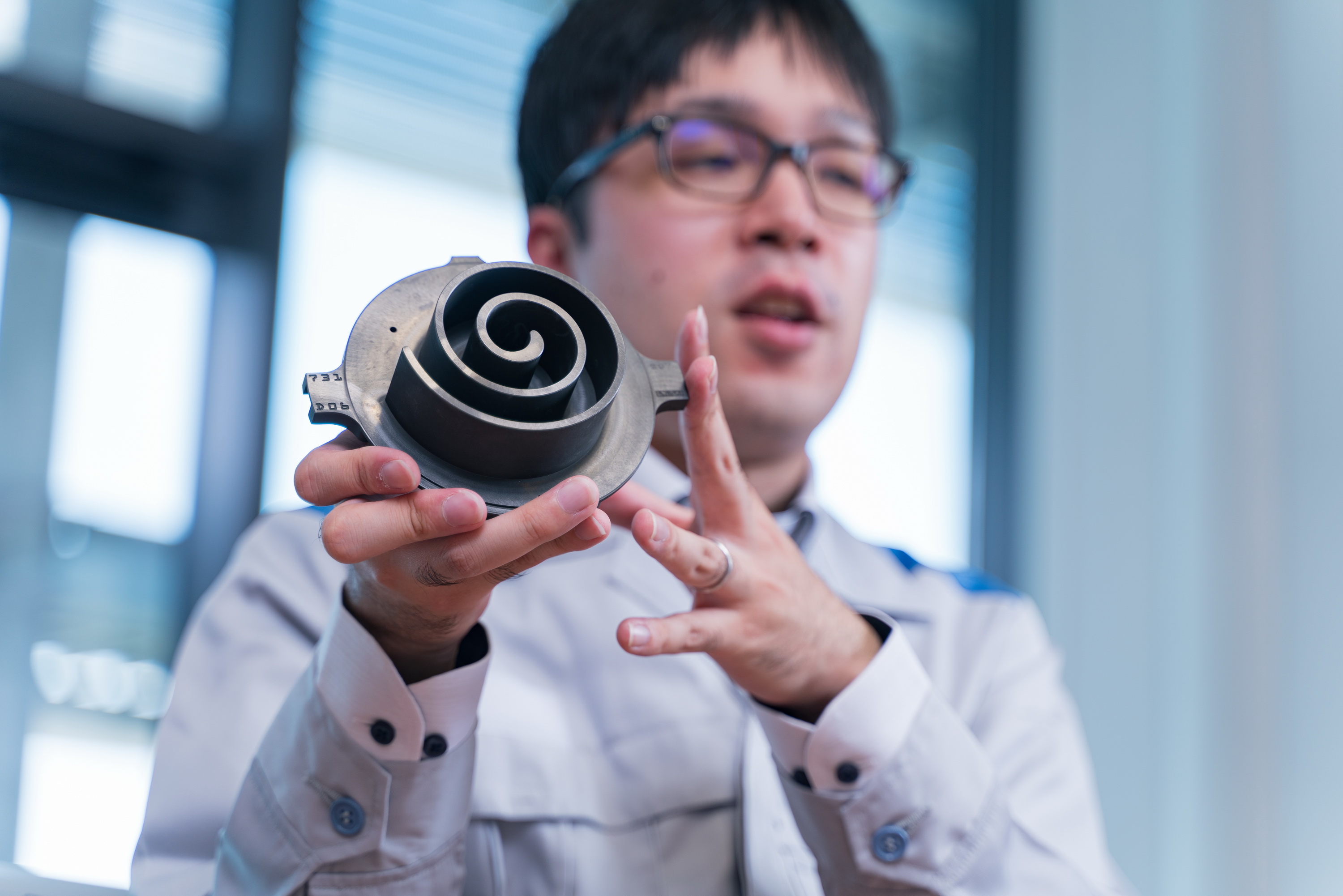

Compressors are one of the key elemental technologies that determine the performance of Daikin Industries' air conditioners. In particular, the two scrolls built into commercial compressors, require high-precision processing and assembly. We interviewed Mr. Yoji Matsumoto, who has developed a new "custom-fit processing" technology that realizes high-precision processing by matching the actual objects. This stands in contrast with conventional “pair processing” technology in which the two scrolls are manufactured using the same machine and tools.

From factory production technologies to R&D for advanced technologies at TIC

--Please tell us about your childhood and school days. Also, why did you choose Daikin Industries?

Matsumoto: My father operated his own forestry machinery business, so I grew up around machinery from a young age. At university, I majored in mechanical engineering and joined Daikin Industries in April 2011 since it had a reputation for being serious about environmental issues. Knowing that I could contribute to the environment through air conditioners had been my motivation for applying.

--What has your career been like since you joined the company?

Matsumoto: My first assignment was to the Production Engineering Department in the Air Conditioning Manufacturing Division where I joined the team in charge of compressors. I spent about four years there working on improving the efficiency of production lines and manufacturing methods at our plants in Japan. Compressor production lines are now highly automated and are places where machine tools, such as machining centers and grinders, play an active role along with robots.

Later, I became involved in support of factories in Thailand and China and also worked onsite at the local factories. From my sixth year, I found myself in the TIC research department, focusing on R&D for advanced technologies for new manufacturing, before being posted to Osaka University for two years. There I continued my work applying the latest technologies to our factories while learning about AI technology and other related areas.

Scroll compressors requiring high-precision processing and assembly

--Could you briefly describe the basic structure and issues of scroll compressors.

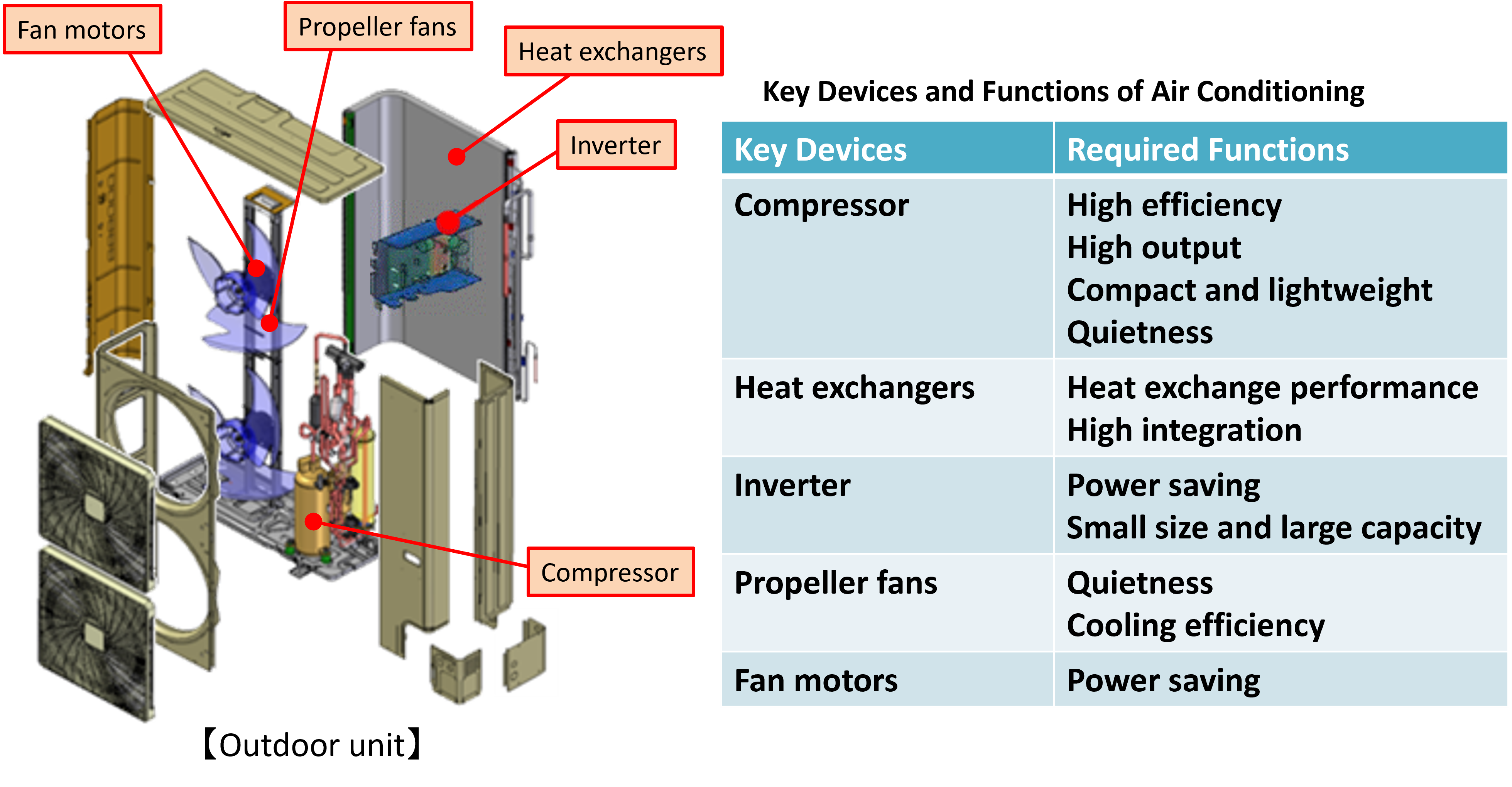

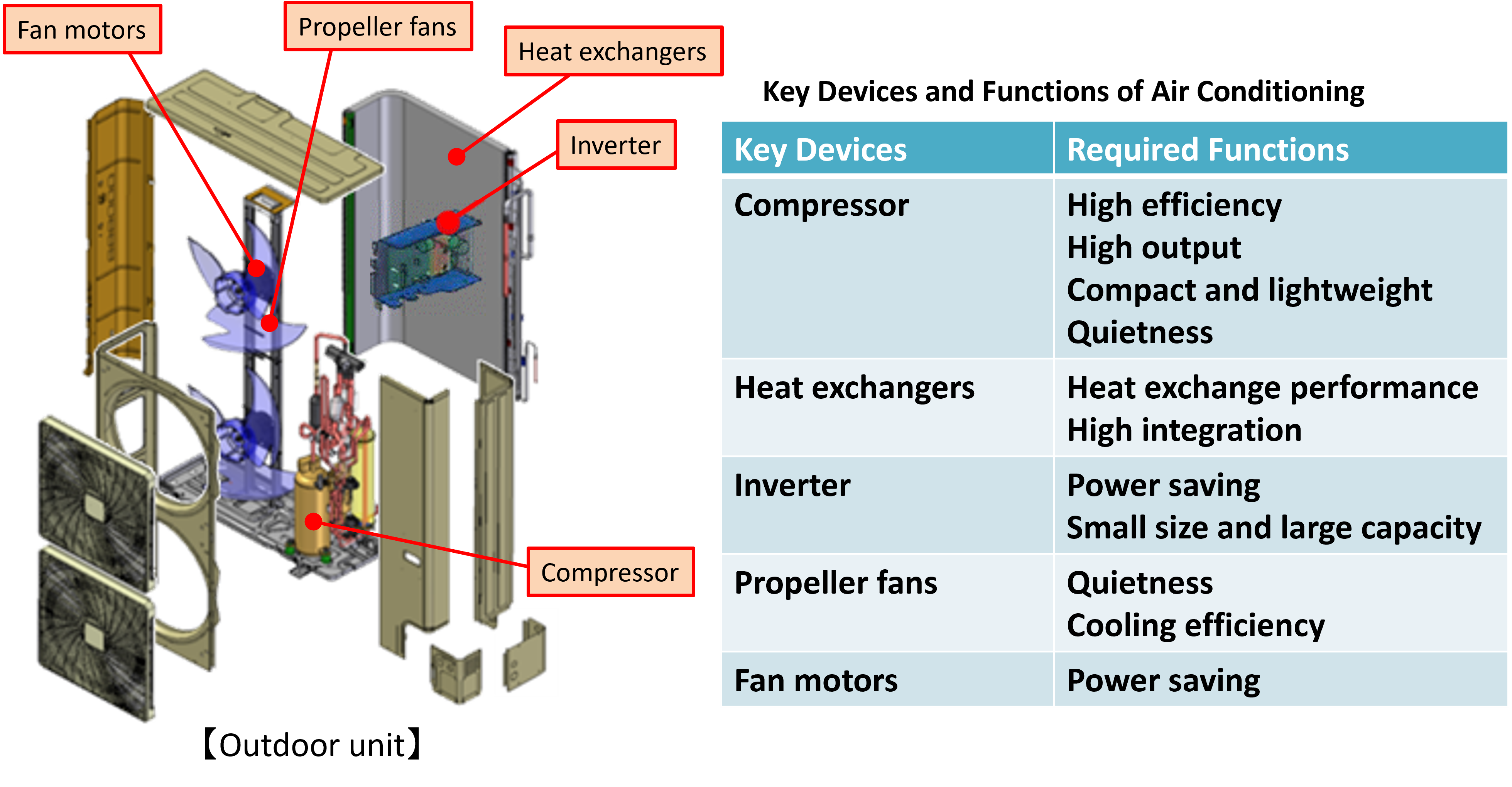

Matsumoto: Key devices in air conditioners include compressors, heat exchangers, inverters, propeller fans, and fan motors. Among these, the compressor is the device that changes the temperature of the refrigerant and uses that temperature in the air conditioner. Compressors are required to have high efficiency and output while being compact, lightweight, and quiet.

Components and required functions of air conditioners. One of the components that determines the performance of an air conditioner is the compressor. High efficiency, high output, compactness, light weight, and quietness are key points.

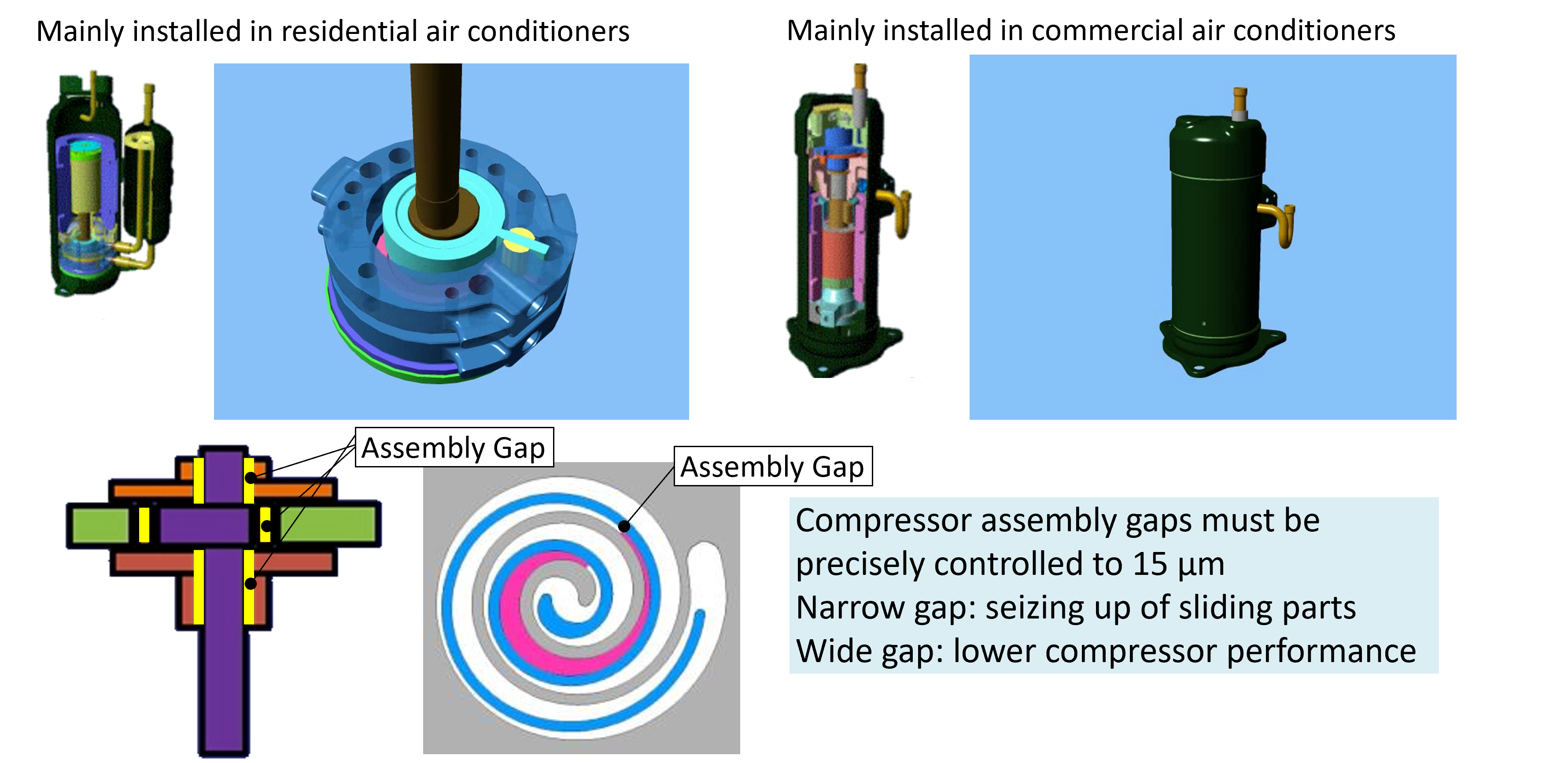

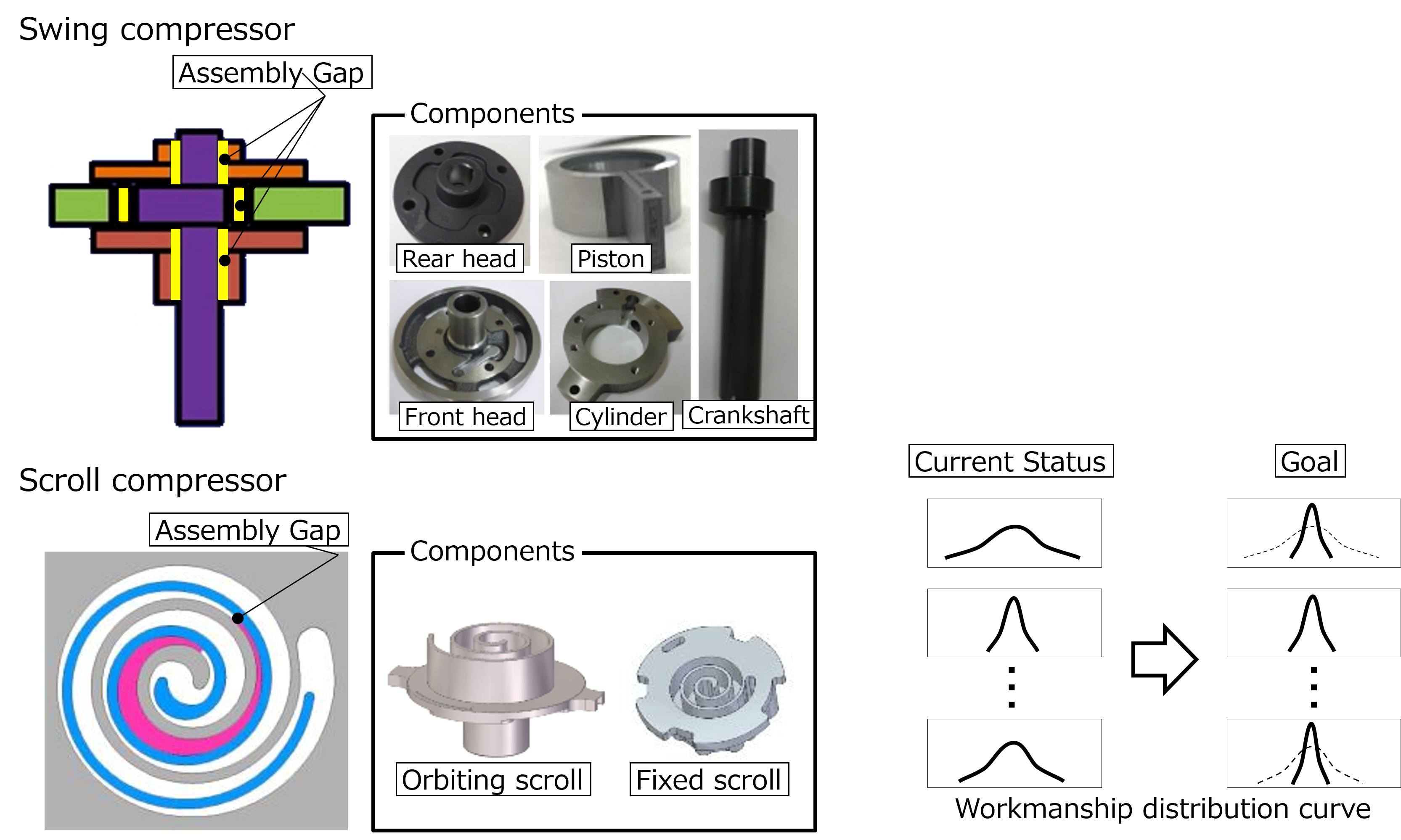

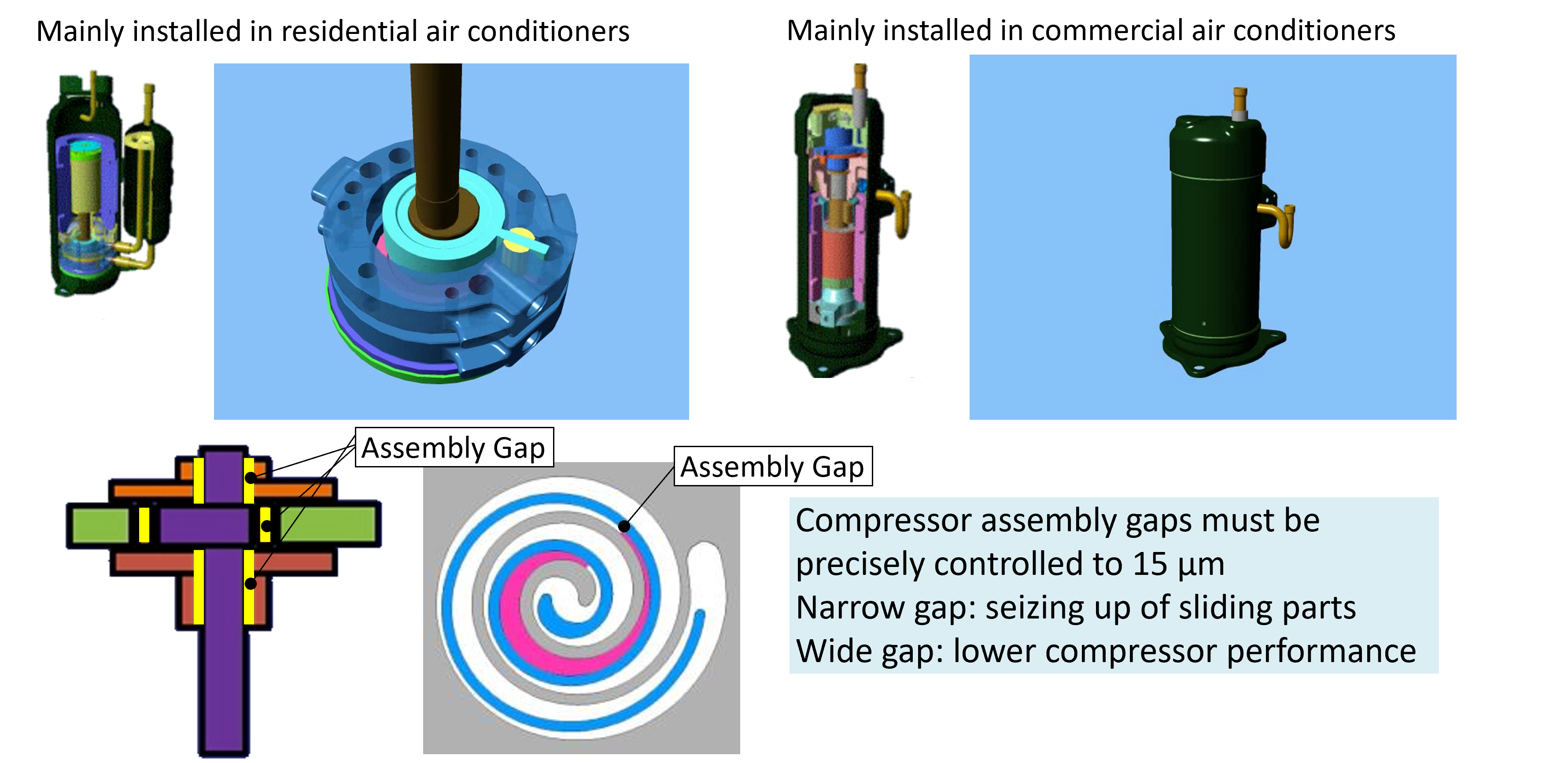

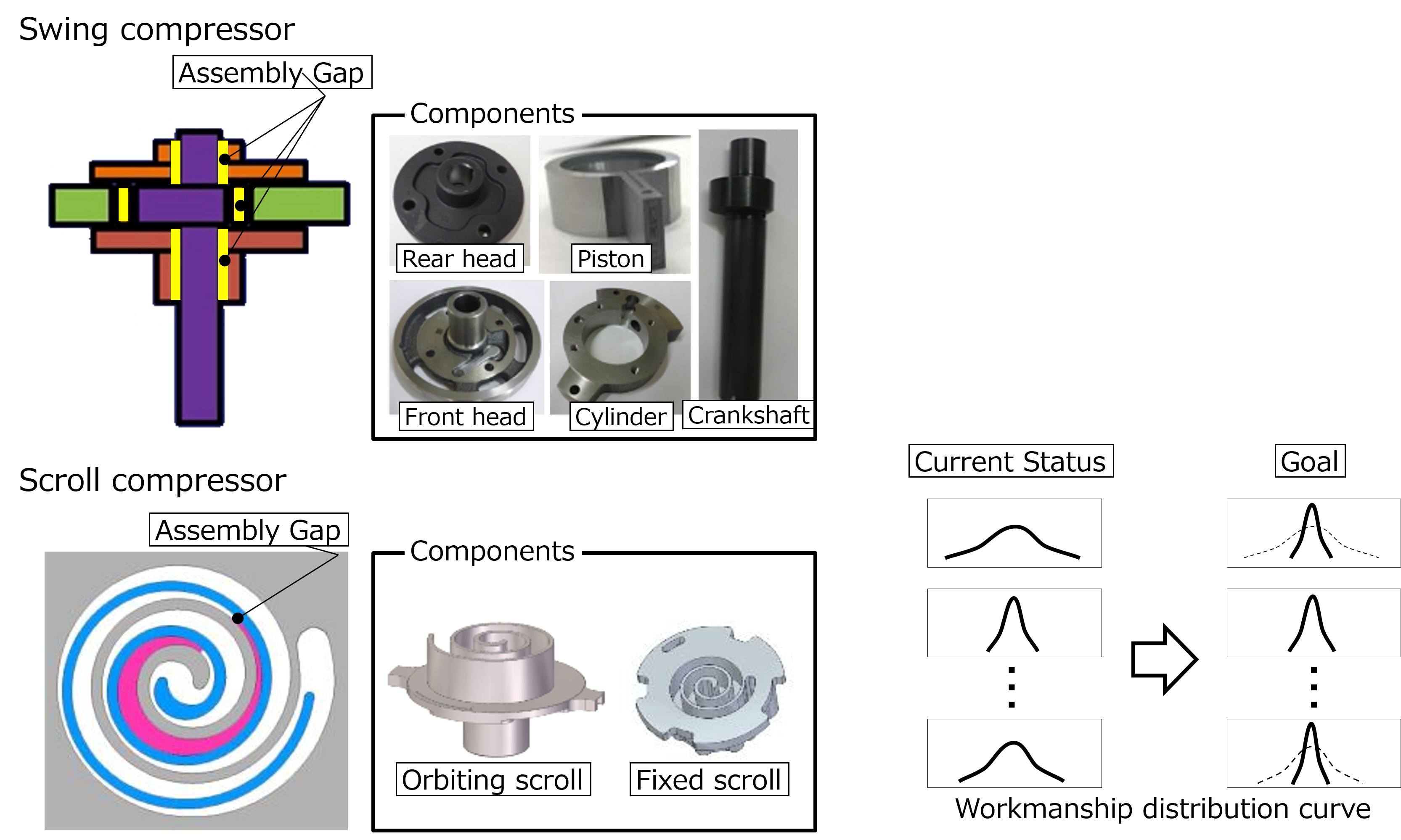

There are two types of compressors used in Daikin Industries' air conditioners: the swing type, which is often used in residential air conditioners, and the scroll type, which is often used in commercial air conditioners. The structure of the scroll type compressor consists of a spiral-shaped fixed scroll in the compression chamber and an orbiting scroll that slides along with it to draw in refrigerant gas and release the gas at the center point of the spiral where compression is greatest.

Compressors used in Daikin air conditioners can be broadly classified into swing compressors for residential use and scroll compressors for commercial use. Compressors require high-precision processing and assembly.

To compress refrigerant gas efficiently, the refrigerant gas in the compression chamber must be confined as much as possible to prevent leakage. Therefore, the gap between the two scrolls must be made as narrow as possible during assembly. However, if the gap is too narrow, the parts contact each other and the sliding parts seize up. This is where scroll gasket management becomes important, requiring high-precision processing and assembly of each part. In conventional processing, two scrolls are manufactured using the same machine and tools in "pair processing" to minimize workmanship error in the machined product.

High-precision scrolls provided through Custom Fit Processing

--Could you give us some details about Custom Fit Processing.

Matsumoto: Since the combination of two scrolls is important, we process the corresponding fixed scroll to fit the orbiting scroll, which was processed first. In doing so, we developed a high-speed, in-line method for measuring the spiral center point and wall thickness. Measurement data is sent to the machining center, which reads the center point coordinates, and then the fixed scroll is ground down.

Custom Fit Processing was developed to manufacture scrolls for scroll-type compressors with high precision. The scroll on the orbiting side is created first, and then the scroll on the fixed side is processed and optimized for matching with the orbiting scroll.

--In other words, you process the parts while performing an "actual product match." The fixed scroll is brought together with the previously manufactured orbiting scroll to maintain a constant gap, and this process is what achieves a custom fit.

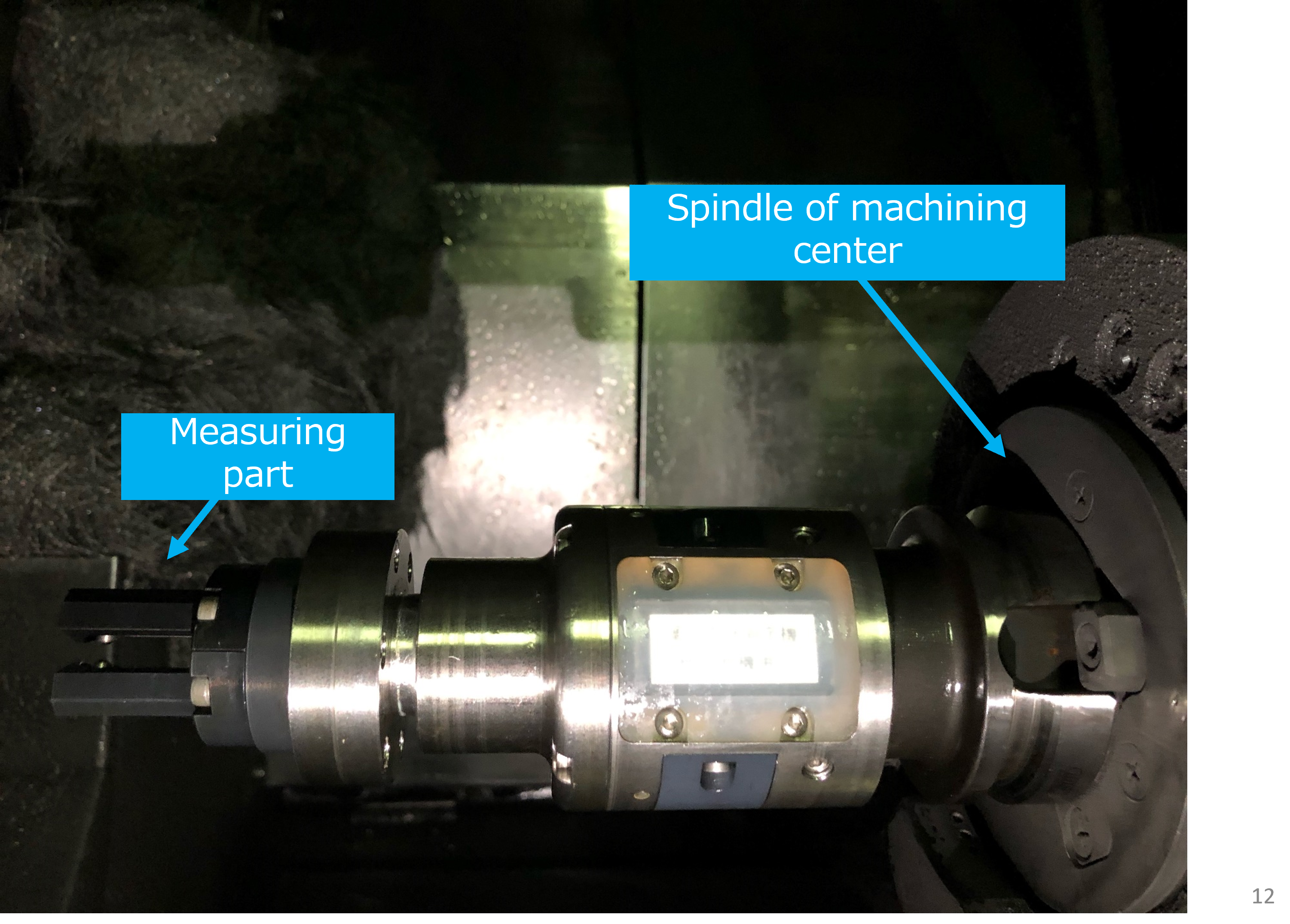

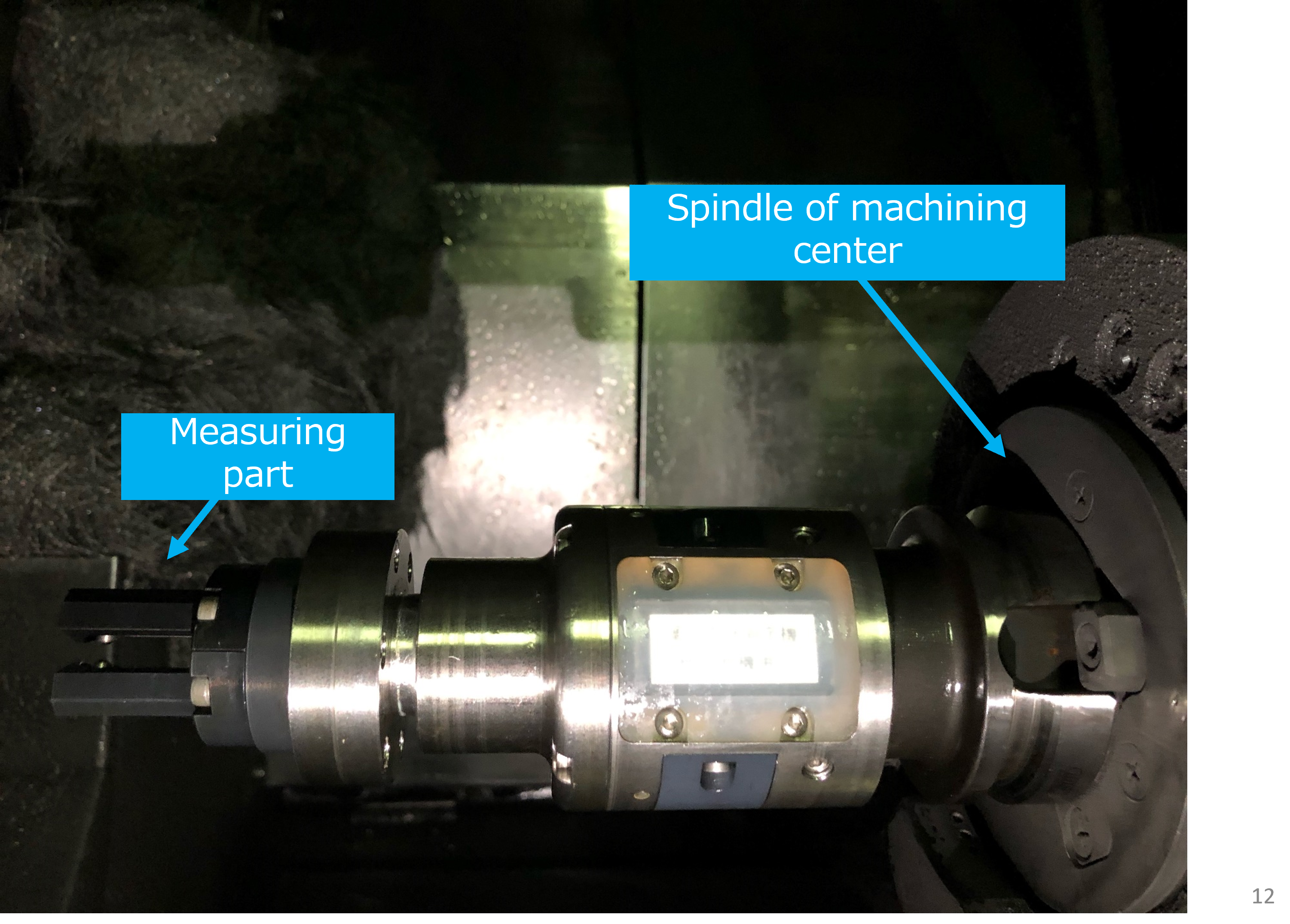

Matsumoto: Yes. And one more thing. In the past, the machining process for the spiral section was difficult and the accuracy of the scroll wall thickness varied. To solve this problem, we developed a new device that measures wall thickness during processing with a machining center. This measurement data is sent via Wi-Fi to the main data system and fed back to the machining center, where high-speed correction is applied during processing to ensure that there are no variations in the finished product. As a result, compressor performance has improved considerably compared to conventional compressors.

Measuring device in the equipment that was built to special order by the manufacturer. A dedicated tool for in-machine measurement is attached to the machining center, and measurement data is fed back during machining for high-speed, high-precision processing.

--How precise is the actual processing now?

Matsumoto: In the past, we had been processing to an accuracy of about ±10 μm, but with Custom Fit Processing, we have achieved a high accuracy of ±5 μm. This accuracy could not have been achieved without the high-speed measurement process because of the effects of material variation, tool wear, thermal expansion, and other factors during processing. In addition, machined parts were sampled and inspected until now with a 3D measuring instrument, but since the development of the dedicated measuring device, the measurement speed has increased eight-fold, making it possible to inspect all parts.

Modification of communication interface for Ethernet/IP legacy equipment

--What were some challenges realized for the key technologies that enable Custom Fit Processing?

Matsumoto: First of all, for high-precision processing, we had a hard time figuring out how to measure while processing. So, we consulted a measuring instrument manufacturer and together we created a unique Daikin device. To achieve the ultimate in precision, we proceeded with development of the device in conjunction with our Quality Control Department.

The most difficult part was the technology to process the parts while adjusting them. The original processing equipment was old and outdated, so the field network communication protocol for exchanging data was incompatible. Therefore, it was necessary to modify the interface to work with Ethernet/IP and match the protocol. Unfamiliar with this area, I closely studied it and developed a system as I went along. Daikin Industries has factories all over the world, so we had to find a way to make the best use of legacy equipment, and this was one of the solutions.

--Was there a particular moment in the development process that gave you great satisfaction?

Matsumoto: The overall project took about two years, and that was a very tight schedule. Even under these circumstances, the various systems worked just as I had envisioned, and as the first prototype began to take shape, I felt a great sense of elation and relief. Since production technology is closely related to the production site, various issues often arose during development and were a source of many hardships, but I received many useful proposals from both the actual workplace and the development department. Because of the trust that we have in each other, we were able to produce a good product, and I am extremely satisfied with the results.

--Do have any advice for other developers and future junior colleagues who want to work for Daikin.

Matsumoto: No matter what you want to do, you cannot carry out the work by yourself. This is why it is important to properly explain your situation and gain the cooperation of the people around you. Daikin Industries has a corporate culture where even young employees are given opportunities to challenge something that they want to do. If you have a sincere desire to accomplish something, you can create something new with everyone together if you fully express that desire. I was able to do it, and I hope that others will follow my example and do their best.

Youji Matsumoto

Technology and Innovation Center

Joined the company in April 2011. Born in Nara Prefecture.

Being responsible for the development of manufacturing technology and methods.

I want to continue challenging myself to develop new, groundbreaking manufacturing techniques that will astonish the world. Additionally, I aim to create environmentally friendly products through the manufacturing process.

Related article