“To output as much as possible within a limited time frame, TIC has an environment in which members discuss plans on a daily basis, share their collective wisdom, and revise plans as needed to move development forward,” said Iwata.

Naturally, both relatively new and senior employees are expected to speak up and actively participate in discussions to generate good ideas. When discussions become heated and show no signs of progress, a top-level veteran employee will often join the discussion and offer advice.

"I think one of greatest attributes of TIC is the absence of any horizonal or vertical barriers (between departments). All employees work together to implement the various phases of the development cycle. Even from an engineer's point of view, I like the fact that we can discuss things in a flat manner," he says in describing TIC and its appeal.

NEWS

Compressor Development Responsibilities and Appeal for Fifth-year Employee

FEATURE

2022.10.25

Five years after graduating university and joining the Technology and Innovation Center (TIC), which oversees basic technology and prototype development of air conditioners, Arihito Iwata battles as assistant team leader in the daily grind of developing new compressors. Recently, he was asked about the atmosphere at TIC that brings out the best in its employees, the environment at the development site, and his own personal aspirations.

Shocked by the speed in the development cycle

“When interviewing with machinery manufacturers, I searched for a company with the world's No. 1 market share without restricting myself to any industry in particular. I thought that if a company had the world's No. 1 market share, then it would also be the world leader in technology," explained Arihito Iwata, who began his fifth year at the Technology and Innovation Center (TIC) this year (2022).

Being a mechanic at heart, Iwata loved tinkering with machines and motorcycles as a student and would often go touring on his motorbike. He first heard of Daikin Industries in university and knew it well from the good things that the upper-level students had said about it. Daikin established TIC in the 2015 which coincided with the time of his job search.

In speaking of his interest in joining the company, Iwata said, "Daikin Industries was on the verge of starting something new at TIC, and I had always been interested in environmental solutions. Seeing that Daikin Industries was actively developing technologies to solve environmental problems, I thought, ‘This sounds interesting to me.’”

In 2017, he achieved his coveted wish of being assigned to TIC where for the past five years he has been involved in research and development, focusing exclusively on compressors. What first surprised him after starting work at TIC was the speed in development. As is typical of research and development, clear work deadlines* are almost nonexistent. However, the pace of the prototyping cycle, even for the creation of a single prototype, struck him as extremely fast.

*: Deadlines depend on the R&D aim

Being a mechanic at heart, Iwata loved tinkering with machines and motorcycles as a student and would often go touring on his motorbike. He first heard of Daikin Industries in university and knew it well from the good things that the upper-level students had said about it. Daikin established TIC in the 2015 which coincided with the time of his job search.

In speaking of his interest in joining the company, Iwata said, "Daikin Industries was on the verge of starting something new at TIC, and I had always been interested in environmental solutions. Seeing that Daikin Industries was actively developing technologies to solve environmental problems, I thought, ‘This sounds interesting to me.’”

In 2017, he achieved his coveted wish of being assigned to TIC where for the past five years he has been involved in research and development, focusing exclusively on compressors. What first surprised him after starting work at TIC was the speed in development. As is typical of research and development, clear work deadlines* are almost nonexistent. However, the pace of the prototyping cycle, even for the creation of a single prototype, struck him as extremely fast.

*: Deadlines depend on the R&D aim

Opportunities for young people to gain experience by taking on challenging projects

Despite having only been in the company for five years, Iwata is now in charge of compressor development at TIC. Compressors are one of the most important elemental technologies in air conditioners. Installed to the outdoor unit, the compressor serves as the heart of an air conditioner in circulating refrigerant, which corresponds to an air conditioner’s blood. The design and processing precision of the compressor is similar to that of an automobile engine.

Prior to joining Daikin, Iwata had never used a CAD program, but senior colleagues taught him the basics, and he took charge of one area of parts design. He soon progressed to doing increasingly more difficult things unassisted and after three years was entrusted with designing important parts, including a rotary shaft and bearings for a compressor. Gradually, he has been given more responsibility for managing the team and was selected to be in charge of the overall structural design of prototypes used for model changes.

Prior to joining Daikin, Iwata had never used a CAD program, but senior colleagues taught him the basics, and he took charge of one area of parts design. He soon progressed to doing increasingly more difficult things unassisted and after three years was entrusted with designing important parts, including a rotary shaft and bearings for a compressor. Gradually, he has been given more responsibility for managing the team and was selected to be in charge of the overall structural design of prototypes used for model changes.

“Not just in the area of shaft and bearing design, but also from the standpoint of overall system design, we have to ask ourselves, ‘What can be done to improve compressor shape, component layout, and refrigerant channel? And what refrigerant should be charged and how can we increase efficiency?’ My team and I are building and evaluating prototypes, and the opinions of all team members are incorporated in the process.”

Even for the core elemental components of air conditioners, it is not unusual for young employees like Iwata, who has only worked in the company for five years, to have an opportunity to challenge an important assignment, and this is a part of the TIC culture.

“What’s unique about TIC is that young engineers increasingly become entrusted with even more work. In addition to their own main work, they are assigned other jobs to hone their skills. I appreciate that my supervisor gives me good opportunities to grow."

Even for the core elemental components of air conditioners, it is not unusual for young employees like Iwata, who has only worked in the company for five years, to have an opportunity to challenge an important assignment, and this is a part of the TIC culture.

“What’s unique about TIC is that young engineers increasingly become entrusted with even more work. In addition to their own main work, they are assigned other jobs to hone their skills. I appreciate that my supervisor gives me good opportunities to grow."

Daily grind in development of a next-generation compressor

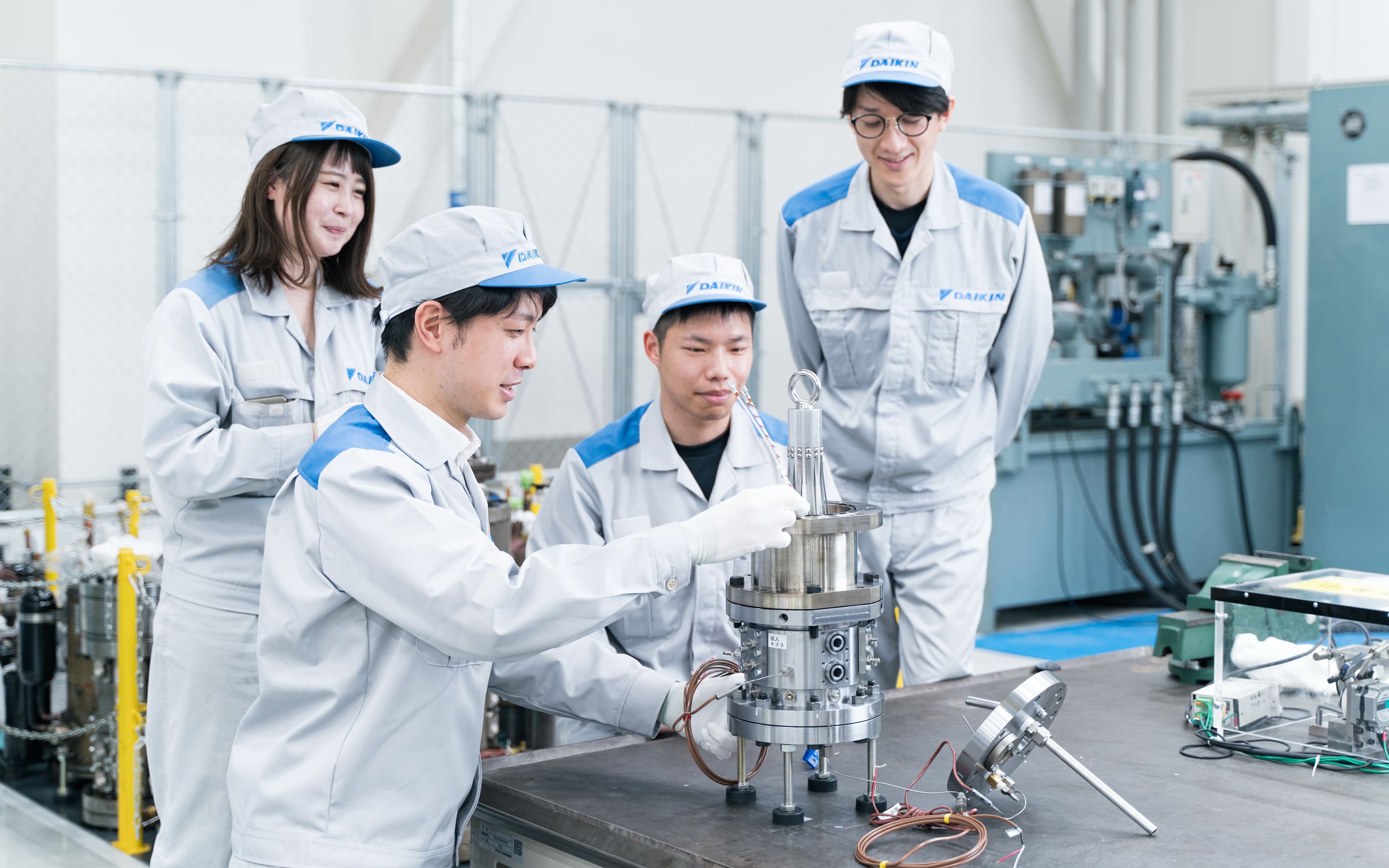

The team, including Iwata, consists of seven people with one mid-career hire. According to Iwata, Daikin Industries actively hires career people from outside the company to gain new knowledge. Team members and their leader Iwata are mainly young people in their early 30s who take charge of their individual roles. Their daily routine as a team is to report progress at meetings, communicate with each other, and decide the next policy together.

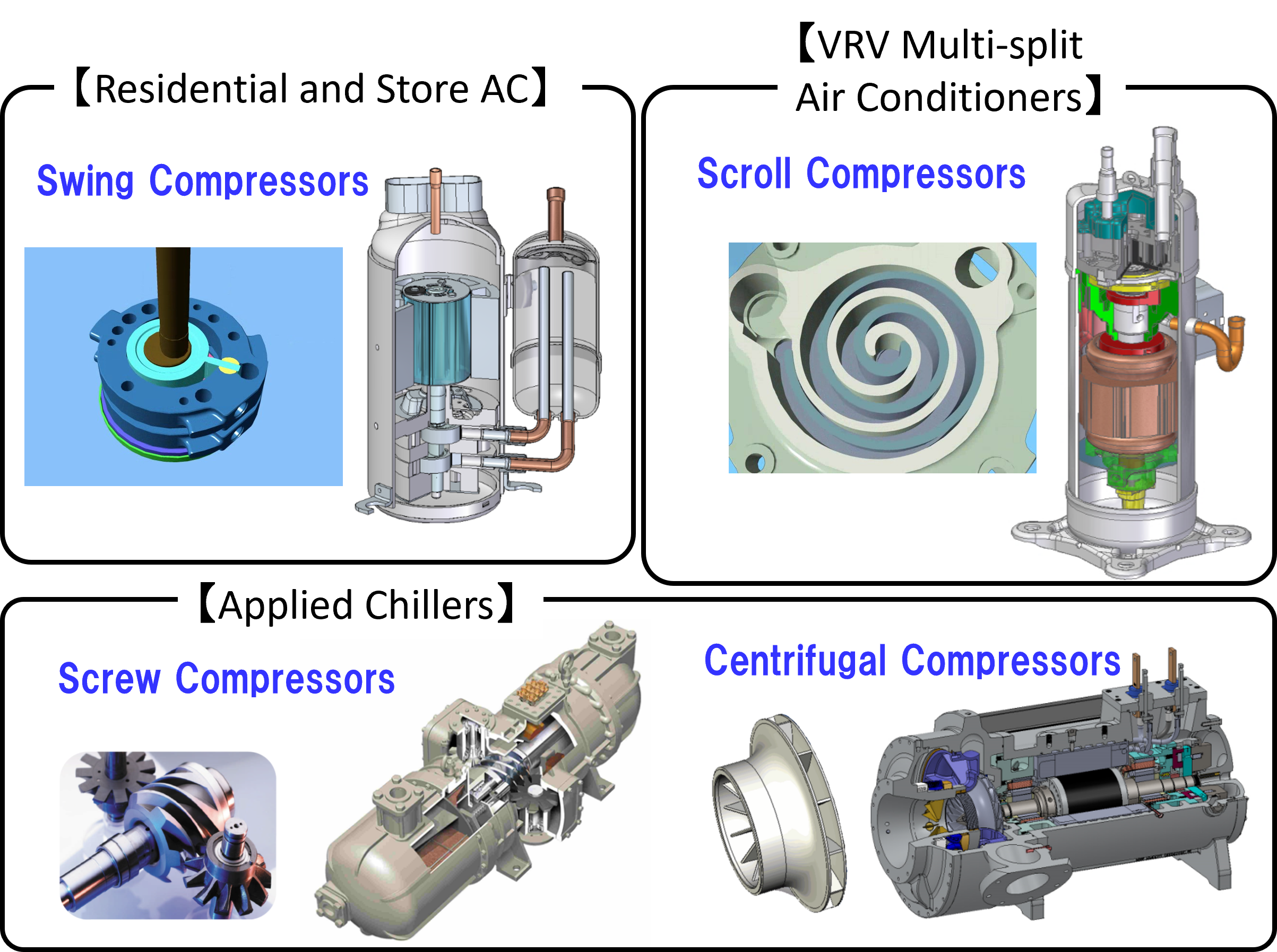

To date, Daikin Industries has developed four main types of compressors: swing, scroll, screw, and centrifugal. These are classified for different applications by cost and capacity. The compressor that Iwata's team is currently developing is a completely new concept for Daikin’s next-generation centrifugal compressor. For this reason, the team has spent several years up to this point on development.

To date, Daikin Industries has developed four main types of compressors: swing, scroll, screw, and centrifugal. These are classified for different applications by cost and capacity. The compressor that Iwata's team is currently developing is a completely new concept for Daikin’s next-generation centrifugal compressor. For this reason, the team has spent several years up to this point on development.

These are types of compressors that Daikin has developed in-house. They are classified according to application by capacity and cost, and Iwata and his team are working to develop a next-generation centrifugal compressor.

“The reason we are taking on the challenge of a new centrifugal compressor is to increase the degree of freedom in designing outdoor units and to achieve lower vibration and noise levels. These advantages are expected to increase user satisfaction, reduce costs through the reduction of soundproofing materials, and simplify assembly," explains Iwata.

In the design stage, the company makes full use of simulation and analysis technology. This allows the company to determine its development policy for compression efficiency, damping performance, and other factors, and then to actually manufacture and evaluate prototypes accordingly. If performance fails to meet the target, work is reevaluated, reworked and perfected. This process is constantly being repeated.

"In the case of compressors, it is necessary to conduct a thorough verification using actual equipment, not just preliminary analysis. That is why it is important to make prototypes, and that is what makes it interesting.”

In the design stage, the company makes full use of simulation and analysis technology. This allows the company to determine its development policy for compression efficiency, damping performance, and other factors, and then to actually manufacture and evaluate prototypes accordingly. If performance fails to meet the target, work is reevaluated, reworked and perfected. This process is constantly being repeated.

"In the case of compressors, it is necessary to conduct a thorough verification using actual equipment, not just preliminary analysis. That is why it is important to make prototypes, and that is what makes it interesting.”

Nevertheless, when working in product development in a new field, things often do not go as expected. When a result differs from the original plan, opinions are not only solicited from within the team, but also from people in other groups, as mentioned at the beginning of this article.

Iwata observes, “Compressors are the sum of many elemental technologies such as motors and inverters. We report any problems that we encounter to the various departments and investigate the causes as early as the day of the problem. Since there is a limit to what we can do on our own, it is important to involve other groups in the development process.”

Because TIC has assembled all the product development and engineering groups together in one building, it is easy for teams to cooperate with each other. One member can easily talk with another to ask for advice. Not only can people ask for help during development, but they can also make requests for the next prototype design by telling others, "This is the type of efficiency we’re looking for.” TIC's great strength lies in its ability to develop products based on overall optimization, whereas other companies develop products based on individual optimization for each element.

Iwata observes, “Compressors are the sum of many elemental technologies such as motors and inverters. We report any problems that we encounter to the various departments and investigate the causes as early as the day of the problem. Since there is a limit to what we can do on our own, it is important to involve other groups in the development process.”

Because TIC has assembled all the product development and engineering groups together in one building, it is easy for teams to cooperate with each other. One member can easily talk with another to ask for advice. Not only can people ask for help during development, but they can also make requests for the next prototype design by telling others, "This is the type of efficiency we’re looking for.” TIC's great strength lies in its ability to develop products based on overall optimization, whereas other companies develop products based on individual optimization for each element.

Future dream of designing a compressor for a super-efficient innovative air conditioner

Iwata, who is developing a new compressor while overcoming various hurdles, says he is experiencing a different sense of accomplishment that comes from realizing the overall design of a compressor for the first time.

Looking back, he says, “The compressor that we are currently overseeing is comparable to a full model change for an automobile. We started from a point where we didn't even know if what we had designed would really work. I was very happy when the first prototype worked. The hurdle may seem low, but when I was able to confirm that the compressor that I had been involved with from the beginning was operating properly and compressing refrigerant, I felt a sense of accomplishment.”

Looking back, he says, “The compressor that we are currently overseeing is comparable to a full model change for an automobile. We started from a point where we didn't even know if what we had designed would really work. I was very happy when the first prototype worked. The hurdle may seem low, but when I was able to confirm that the compressor that I had been involved with from the beginning was operating properly and compressing refrigerant, I felt a sense of accomplishment.”

In recent years, the global trend toward carbon neutrality has accelerated, and Daikin Industries has made it a top priority in its growth strategy. Of course, decarbonization is also an important perspective in compressor development. Focus is on replacing refrigerants that impact the environment and replacing them with oxygen- and carbon-free ones, and the company is in the process of searching for and evaluating new refrigerants.

Iwata, who has been interested in environmental issues since he was a student, says of his aspirations, "Whether or not I can really achieve it, I would like to create an innovative compressor with super efficiency. Air conditioners consume a large amount of electricity, and the compressor accounts for most of the power consumption. If the compressor becomes eco-friendly, it could drastically reduce the amount of electricity used throughout the world and contribute to improving the global environment by reducing the operation rate of thermal and nuclear power generation. This may still be a long way off, though," he says.

Iwata, who has been interested in environmental issues since he was a student, says of his aspirations, "Whether or not I can really achieve it, I would like to create an innovative compressor with super efficiency. Air conditioners consume a large amount of electricity, and the compressor accounts for most of the power consumption. If the compressor becomes eco-friendly, it could drastically reduce the amount of electricity used throughout the world and contribute to improving the global environment by reducing the operation rate of thermal and nuclear power generation. This may still be a long way off, though," he says.

Finally, Mr. Iwata offered the following message to readers.

“The beauty of Daikin Industries is that if you have a passion for engineering and speak up by saying, ‘Let me do this design and development,’ you will likely be entrusted with the task. For those engineers who are seeking employment, thinking about changing jobs, or wanting to create products for the world, Daikin Industries is a company where you can reflect your own will and realize what you want to do. If you have a challenging spirit and want to test your abilities to the fullest, I highly recommend coming to work at TIC."

“The beauty of Daikin Industries is that if you have a passion for engineering and speak up by saying, ‘Let me do this design and development,’ you will likely be entrusted with the task. For those engineers who are seeking employment, thinking about changing jobs, or wanting to create products for the world, Daikin Industries is a company where you can reflect your own will and realize what you want to do. If you have a challenging spirit and want to test your abilities to the fullest, I highly recommend coming to work at TIC."

Arihiro Iwata

Technology and Innovation Center

Joined the company in April 2017. Born in Aichi, Japan.

He is a member of the development team for a new type of compressor. He is working hard every day to create a new type of compressor with ultra-high efficiency that does not yet exist in the world.

Technology and Innovation Center

Joined the company in April 2017. Born in Aichi, Japan.

He is a member of the development team for a new type of compressor. He is working hard every day to create a new type of compressor with ultra-high efficiency that does not yet exist in the world.

Related article