Aiming to Develop Compressors with High Thermal Efficiency and Earth-Friendly Air Conditioners!

Daikin is constantly developing various elemental technologies to bring new environmentally conscious air conditioners to the market. In particular, the compressor, which is the heart of industrial air conditioners, is the key to AC development and must meet a variety of conditions. We interviewed Kosuke Nishimura, who is currently developing compressors for air conditioners on the frontlines as Senior Engineer of the Compression Technology Group at the Technology and Innovation Center (TIC).

Increasing demand for air conditioners and environmental technologies

− Can you tell us about your career before and after joining Daikin Industries?

Nishimura: I gained knowledge of fluid machinery during my master's program at Osaka University while conducting my research on “two-stage centrifugal blood pumps" and “axial vibration caused by the sloshing phenomenon.” I decided to work for Daikin Industries because it handles consumer products and has a global presence and also because I wanted to utilize the technology that I had learned at university and have people around me use products incorporating that technology.

Since joining the company, I have been mainly responsible for the development of elemental technologies and advanced technologies for compressors.

− Please tell us about the current state of compressors and the challenges involved with them.

Nishimura: First, the market for air conditioners is changing, and compressors are an elemental technology for them. According to the International Energy Agency (IEA), the global air conditioner market is expected to expand three times its current size by 2050. Since the energy consumption of air conditioners and water heaters now accounts for about 40% of total energy use, the percentage of energy consumption from air conditioners will continue to increase. Therefore, energy conservation has become an urgent issue.

Another movement is the global focus on CO2 emissions reduction and carbon neutrality. This movement has led to restrictions on boilers and other combustion-based heating in Europe and the United States. As a result, combustion-based heating is being replaced by heat pumps. Similarly, air conditioners require refrigerant (working fluid) to transfer heat, and since the substances used in current refrigerants (HFCs) have a significant impact on global warming, restrictions have been placed on their use. These needs are the driving force behind moving air conditioners toward becoming more environmentally conscious and having a lower environmental impact.

Comparison of important heat pump mechanism with a bucket relay

− I see. So, there is a need for compressors with better environmental performance. What are some of the new ideas for the core technology?

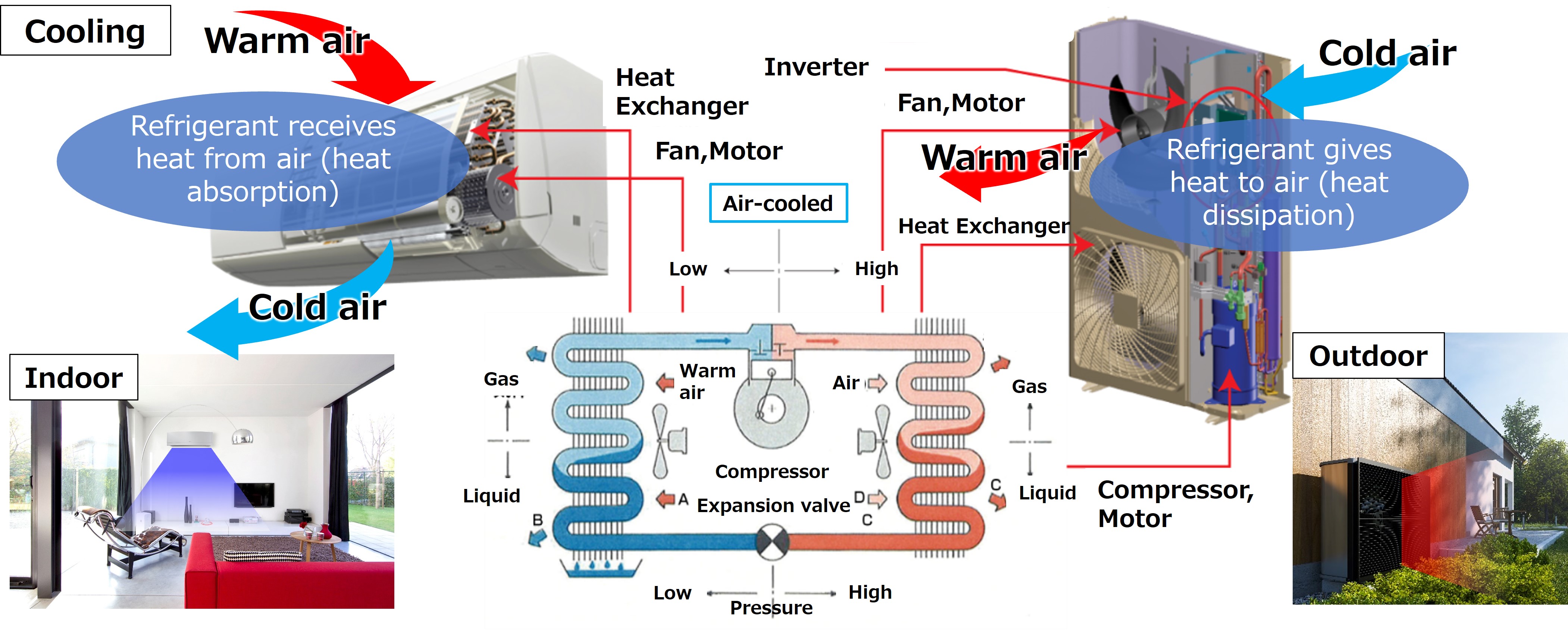

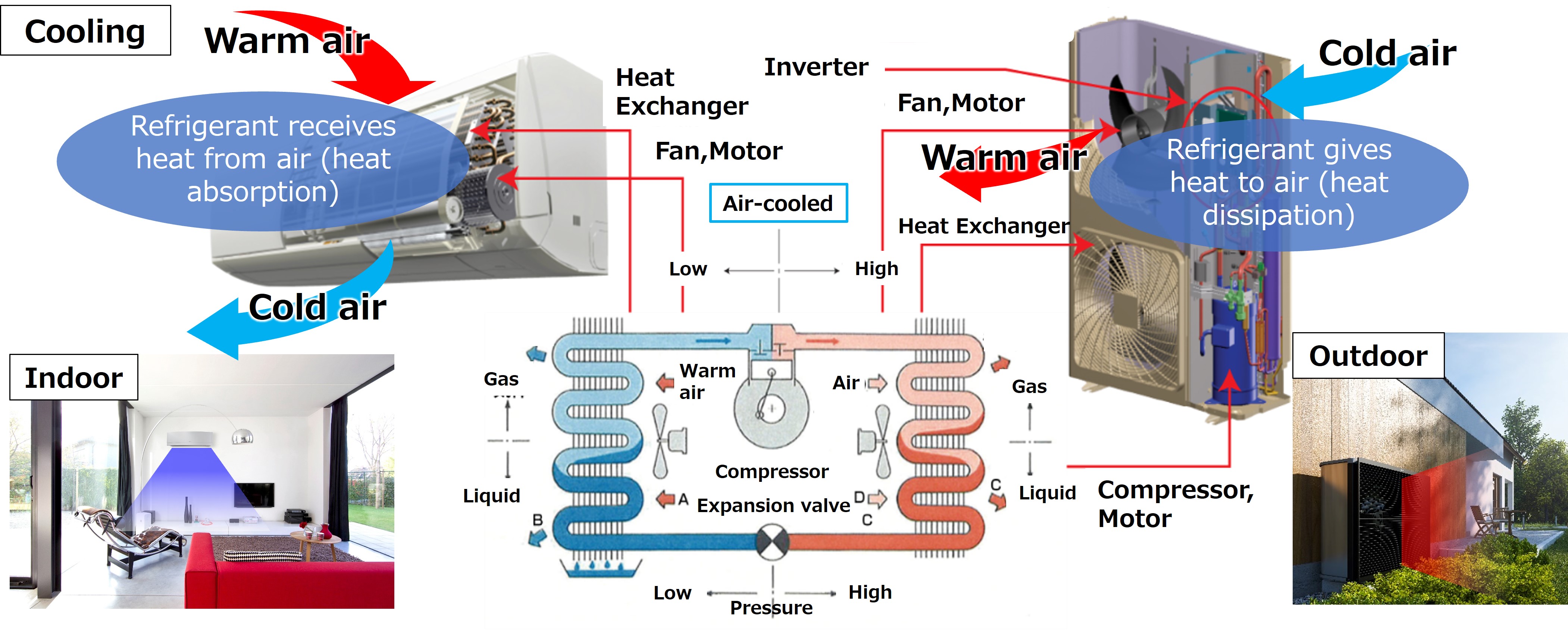

Nishimura: Almost all of our air conditioners have an important technology called a "heat pump," which uses heat collected from the outdoor air as indoor energy requiring very little input energy (electricity). The latest air conditioners with heat pumps provide seven times more thermal energy than input energy. In this process, the refrigerant is responsible for transferring heat between the indoor and outdoor air.

The compressor (in the outdoor unit) increases refrigerant pressure and temperature, enabling refrigerant to flow into the piping connecting the outdoor and indoor units and transfer heat to and from the indoor air through the heat exchanger (in the indoor unit). Greater heat can be transferred by the heat of vaporization and condensation as the refrigerant evaporates and condenses in the compressor and heat exchanger.

The role of heat pumps used in air conditioning is to pump heat in and out and use that heat as energy for heating and cooling.

− Could you elaborate on the principle behind heat pumps?

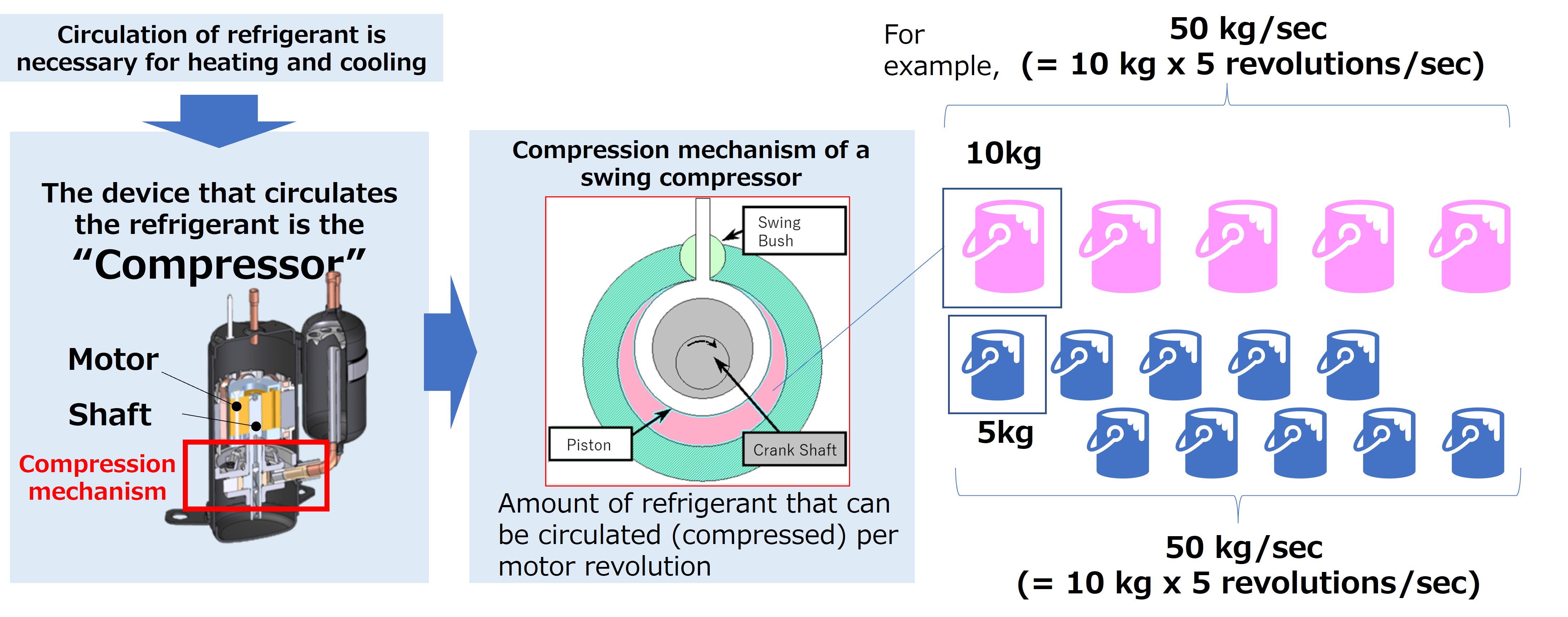

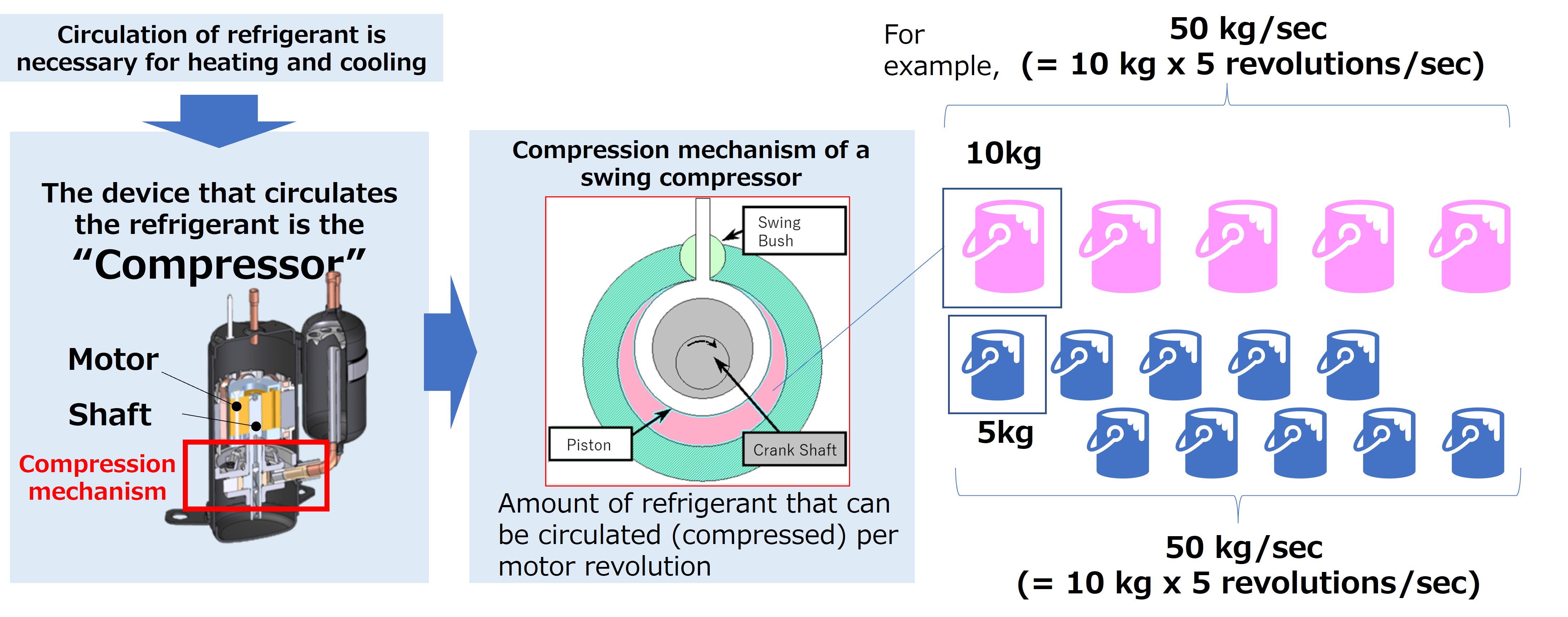

Nishimura: To heat and cool, it is necessary to circulate the heat-carrying refrigerant. As such, the heating and cooling capacity of a heat pump can be easily understood by comparing it to refrigerant carrying heat in a bucket relay. When the heat capacity of the bucket carrying a fixed amount of heat is reduced, then the number of buckets needed to maintain the same amount of heat must be increased. For example, if a 10 kg bucket is being carried at 5 rotations per second, the same amount of heat can be carried at 10 rotations per second with a 5 kg bucket .

The principle of a heat pump can be easily understood by comparing it to a bucket relay. To transfer the same amount of heat (heat of the refrigerant gas) in a bucket of half the capacity, the number of bucket relays (speed of circulating refrigerant) needs to be doubled.

Nishimura: Refrigerant is compressed and circulated by the power of the compressor motor. If the amount of refrigerant compressed at one time (= bucket) is reduced, the power required for the compressor is also reduced, which allows the motor to be smaller. This in turn reduces the number of magnets and electromagnetic steel sheets used and has the advantage of reducing overall costs since these are components of the motor. The fact that this high-speed compression technology has enabled us to reduce the use of magnets and other materials is also one of our major strengths.

Unique Daikin technology allowing heat pumps to function even in cold regions

− When using a heat pump to transfer heat, doesn't low outdoor air temperatures reduce thermal efficiency?

Nishimura: That’s exactly right. Heat pumps use heat from outdoor air, so if the outdoor temperature drops too low, the refrigerant gas entering the bucket becomes too diluted to carry sufficient heat. Therefore, we are developing new air conditioners that do not lose efficiency even at low outdoor temperatures. This is done by introducing technology called "injection," which compensates for heating capacity by increasing the amount of high-density refrigerant during compression, and high-speed rotation technology, which increases the number of bucket relays (circulation). Especially for the injection part, we have devised an advanced analysis and evaluation method by simulating the complex three-phase flow of (refrigerant) gas, liquid, and oil.

−Are there any other elemental technologies that you have devised to achieve higher speeds?

Nishimura: Daikin's compressors use a unique swing mechanism(※1) and increasing the speed of the motor causes the performance of the compressor to deteriorate, generating noise and vibration. Centrifugal force causes the motor shaft to deflect at high speeds, which puts a strain on the bearings and makes them susceptible to wear. We have solved the problem of higher speeds by adopting refrigeration oil, ensuring reliability through the adoption of self-developed plain bearings (journal bearings), and utilizing total piston balancing design technology to suppress noise and vibration. Through these advancements, we have created a compressor unmatched by any other company.

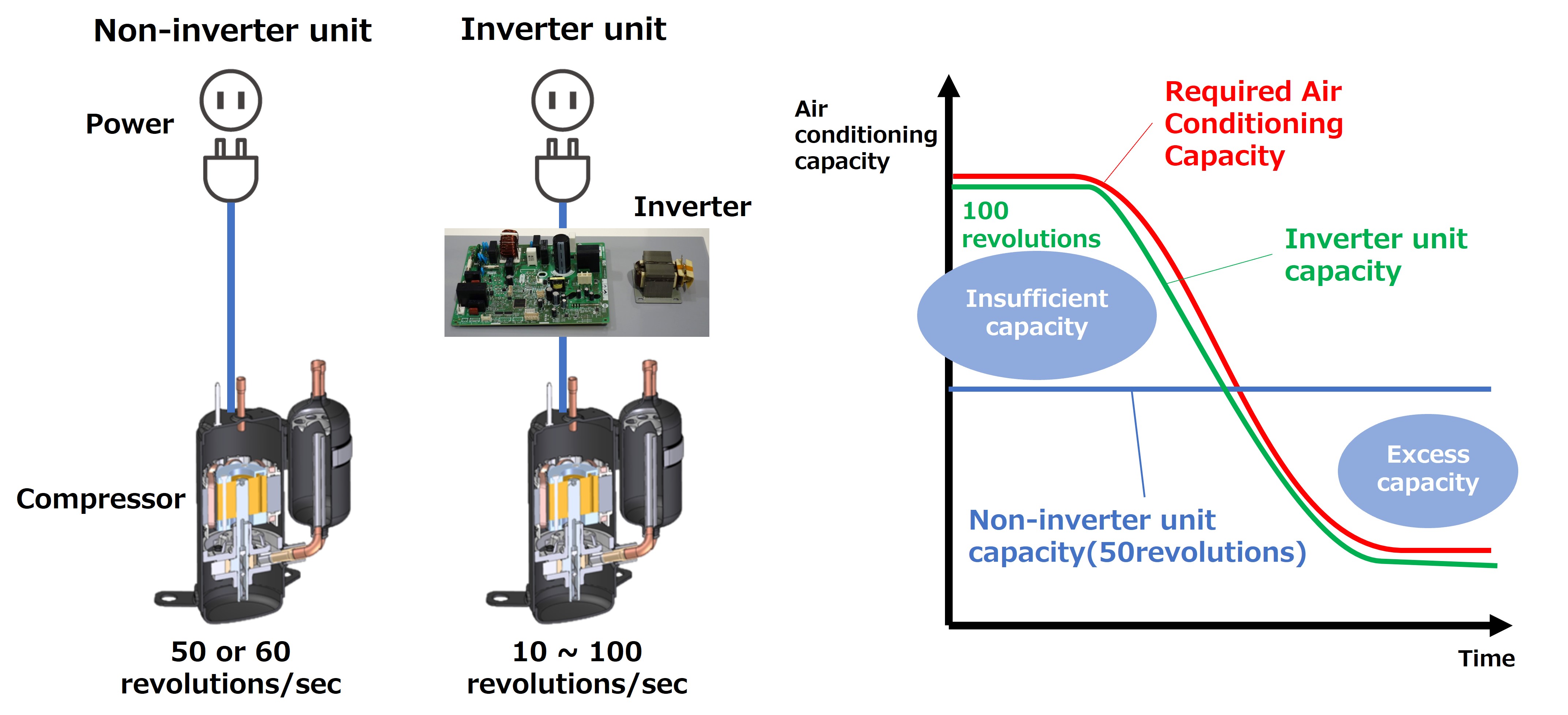

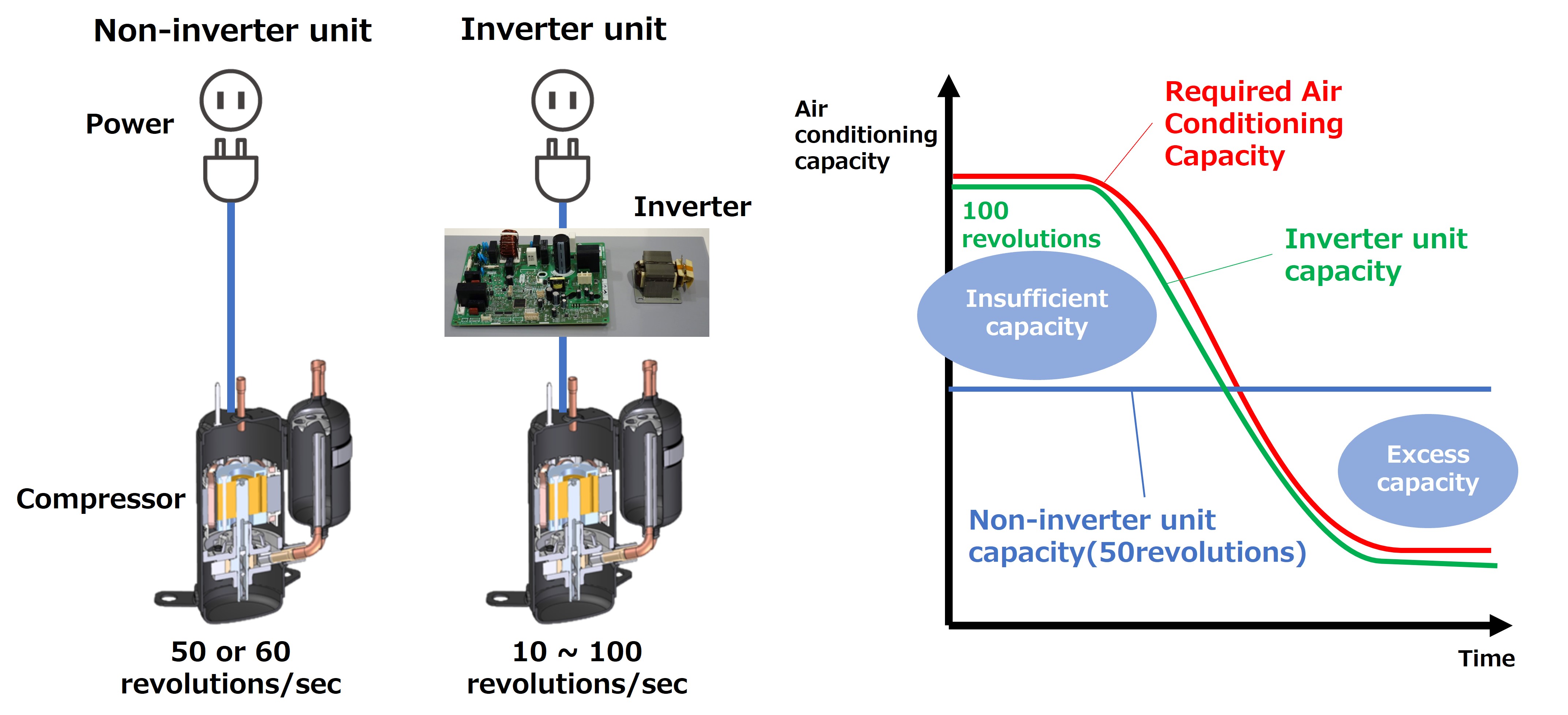

Other features include an ingenious combination of compressor motor and inverter to improve efficiency. The control unit of a compressor motor can be divided into two types: a non-inverter type, in which the rotation speed is determined by the power supply frequency (50/60 Hz), and an inverter type, in which the rotation speed can be freely controlled. Inverter units are developed in-house(※2), and by operating the compressor at the appropriate output for the required air conditioner capacity, we have achieved comfort and energy savings with features including rapid cooling and heating, and suppression of temperature fluctuations.

※1「Differentiating Technologies Support Daikin Compressors」

※2「Electrolytic Capacitor-less Inverters Contribute to Global Environment」

Inverter and non-inverter units differ in their control of motors. Inverter technology enables the motor speed to be freely controlled, improves energy efficiency, contributes to energy conservation, and Daikin has developed its own inverter technology.

Nishimura: Because inverter models are more expensive than non-inverter models, non-inverter models are still preferred in many countries of North America, Asia, the Middle East, and Africa, but Daikin has developed its own unique technology to reduce the number of electrolytic capacitors in inverters and would like to promote widespread use of inverter models. Mechanical parts such as compressors are also designed in line with the development of inverters in an effort to achieve a complete solution exhibiting low-cost and high-efficiency performance.

While many development tasks still remain, only hard work creates superior products

−I think that the energy savings gained from an inverter makes it an environmentally conscious technology that contributes to carbon neutrality.

Nishimura: I totally agree. So, let’s move on to the enormous impact of refrigerant. Basically, refrigerant circulates through the piping of air conditioners, but it can be released into the open air when the piping is broken or poorly installed, or when air conditioners are discarded. The refrigerant "R32," which is widely used today, has a greater impact on global warming than CO2 as seen in an index called global warming potential (GWP), which indicates the magnitude of global warming impact. In this index, CO2 is 1, and R32 is 675.

Therefore, refrigerants in the category of "HFCs (alternatives to CFCs)," which include R32, are beginning to be regulated worldwide. Naturally, it will be necessary to switch from conventional refrigerants to new refrigerants. With the limited refrigerants available in the future, it will be important to refine our technology to achieve performance equal to or better than that of current air conditioners.

−I know that many things are still under development that you cannot talk about, but could you tell us about the current state of development and any difficulties you are having?

Nishimura: I can't give you a specific development status, but we have already started mass production of high-speed technology and have incorporated it in some of our models. If I were to compare the current development status with that of climbing Mount Fuji, I would say that we were at the halfway point (Laughs). The development of air conditioners is a total achievement through the improvement and evolution of each elemental technology, so the mountain is still very high. We are still at the stage of verifying the effects of new refrigerant prototypes to confirm that the new refrigerants do not degrade performance after replacement.

−Finally, do you have any advice for future recruits who may be interested in working for Daikin?

Nishimura: Daikin's corporate culture is described as "Fast & Flat.” Flat means that senior management is knowledgeable about technology and close to the actual worksite, enabling frequent discussions and consultations. This is a big difference from other companies. Even within TIC, there is an openness and borderless communication among groups that develop products other than compressors, such as inverters, heat exchangers, and fans. It is reassuring to know that there are people on the same floor with whom you can consult immediately.

R&D is a job that challenges you to do something that no one has ever done before and is often very difficult work. However, precisely because it is difficult work is the reason that we are able to create differentiated products that are distinctive from those of other companies. Daikin has an environment that allows us to take on new challenges. Conversely, there is an atmosphere at Daikin in which failing to act and take on challenges runs counter to the corporate culture. Therefore, while I might run into a wall every now and then, I can still enjoy the development process since there is always someone around to offer me the advice and support that I need. If you want to challenge something difficult, I highly recommend that you become a member of our team.

Kosuke Nishimura

Senior Engineer, Technology and Innovation Center

Born in Hyogo Prefecture and joined the company in April 2012. He is responsible for compressor technology development.

“We will continue to hone our unsurpassed skills and challenge high technological goals. Likewise, we will consolidate the wisdom of all our people and deliver technologies to the world that make other companies shake their heads in disbelief and say, ‘Daikin has done it again.’”

Related article